Buzz, Squeak and Rattle

Buzz, Squeak & Rattle are sound words that have plagued the automobile industry pretty much since the times of Daimler and Maybach. But while ‘BSR testing’ was once a concern primarily in the luxury car space, today’s consumers have come to expect modestly-priced cars to deliver a quiet ride as well. As a result, acoustical standards have been raised across the board and OEMs are raising acoustical standards throughout their fleets.

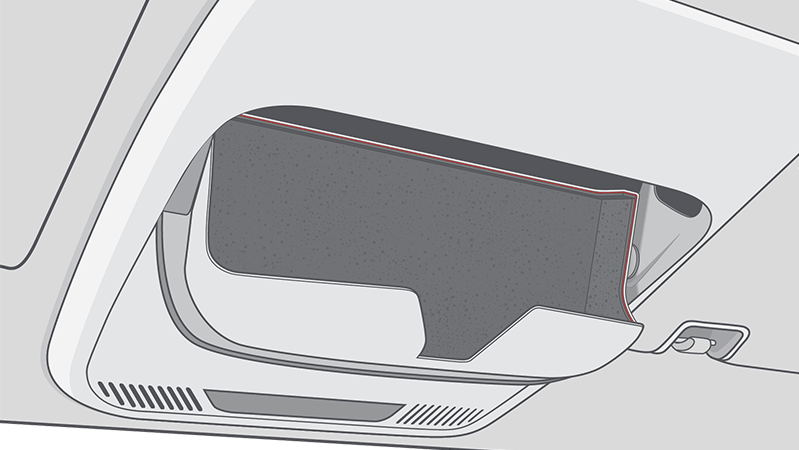

Automotive interior design tapes to help prevent BSR

Avery Dennison offers a variety of solutions to meet those standards. We provide a comprehensive range of adhesives engineered to help prevent BSR. As a market leader with 20+ years of experience as a BSR solutions provider, we continue to develop innovations in the automotive industry

Custom automotive interior innovations

The trend of raising overall standards is complicated by the increasing presence of electric vehicles (EV). EV engineers are quickly discovering the absence of an internal combustion engine eliminates a significant source of noise that had been useful for masking unwanted sound and vibration. The realisation of noises previously unheard, together with the new noises coming from the electrified powertrain, can significantly affect NVH (Noise, Vibration and Harshness) performance, impacting passenger comfort and the perceived interior quality of the vehicle as well as the manufacturer’s brand reputation.

Automotive interior adhesives

Advantages include the broadest range of adhesive offerings from rubber-based, acrylics and silicones. Our portfolio of adhesive tapes offer fine-tuned, customisable solutions that can be laminated to a wide range of low-friction or wear-resistant materials to create BSR solutions.

Flock and felt tapes have become a go-to solution for many BSR engineers, and Avery Dennison offers a variety of solutions for these applications. Engineers can choose from a range of high-performance adhesives that are effective across the spectrum of interior and exterior substrates found in modern vehicles, including LSE components. Our adhesives meet many OEM low VOC specifications.

Brand owners, end users and converters are all looking for solutions that convey a sustainable reputation, strengthen customer service and meet sustainability goals as well as recycling targets. By collaborating with our value chain partners, we can deliver a more sustainable future. It’s all about staying ahead of the curve.

CSS innovations for car interior adhesives

At the same time, while a lot of efforts are focused on reducing chemical emissions (and rightly so), new regulations are set to mark a change as well. The EU’s Chemicals Strategy for Sustainability (CSS), launched in 2020, is a wide-ranging package of measures designed to accelerate the move towards a greener, cleaner economy – and it’s already having an effect on the automotive interior sector.

There is a markable shift in focus for OEMs and tier suppliers who need to think ahead and adapt. Avery Dennison proprietary performance tapes – most notably our innovative UV acrylic adhesives and hotmelt rubbers – offer the solution for the industry of tomorrow.

Resources

Andrew Christie

Market Segment Manager Automotive

Andrew Christie is the Business Development Manager responsible for the Automotive Market at Avery Dennison Performance Tapes. He has introduced many innovative solutions to the automotive interior market including lightweight acoustical materials and sustainable seat fabrics. His commitment to the industry continues with delivering pressure-sensitive adhesives that address the challenges facing the automotive industry today.

andrew.christie@eu.averydennison.com

www.linkedin.com/in/andrew-christie