Electric vehicles are poised to take charge

A long history, a bright future

Back in 1886, a German engineer named Karl Benz began commercial production of the first cars with gasoline-driven internal combustion engines (ICE). Since then, automotive styling has changed dramatically, and technology has evolved to make cars safer, more reliable, faster, and more efficient. However, in many fundamental ways, today’s ICE vehicles are still direct descendants of those early gasoline-powered cars: four wheels (Benz’s first model had three, but four quickly became the standard), mechanical or hydraulic steering and braking systems, and engines powered by rapid combustion of fossil fuel vapor and oxygen.

A new era in vehicle development

We are now entering an era that redefines the automobile. Instead of gradual evolution, we’re witnessing a revolution. More drivers are moving away from the traditional ICE in favor of electric motors powered by state-of-the-art battery packs. In just 12 years since Tesla introduced its first Roadster (one of which is now orbiting the sun between Earth and Mars), electric vehicles are about to become mainstream.

As an October 2020 Forbes article put it: "If the high stakes and recent, almost universal rush by manufacturers to bring fleets of wholly practical EVs to market is a meaningful indicator, we’re fast approaching the EV tipping point. What lies beyond is a future where electric cars are the default and gasoline-powered cars are relics of a carbon-intensive past."

The electric revolution: What’s driving it?

Several trends are fueling this electric revolution. According to Cowen and Company’s September 2020 report, "Future of Mobility Primer," EVs are expected to capture a 9.5% market share by 2025 and 25.7% by 2030.

Costs: EVs will become more affordable than ICE vehicles early in the 2020s, driven by declining battery costs and increasing ICE costs related to carbon emission and fuel-efficiency requirements.

Policy: Policymakers worldwide are enacting measures to speed up EV adoption. For example, California has announced a ban on the sale of new ICE vehicles by 2035. Several European countries and the UK plan to phase out ICE vehicle sales, with most bans starting between 2025 and 2030.

OEM Aspirations: More automakers are setting ambitious goals to go all-electric in response to shifting consumer preferences and regulatory changes. General Motors plans to be all-electric by 2035, while Volvo aims for 50% of its sales to be fully electric by 2025.

Innovation: Battery technology is advancing rapidly. EV ranges are increasing, charging times are decreasing, and engineers are addressing early concerns about EV batteries. For example, a standard Tesla Model 3, which retails for $33,690 with EV incentives, offers a range of 263 miles, a 200-mile charging time of just 15 minutes at one of the company’s 20,000 Superchargers, and a 0-60 time of 5.3 seconds—comparable to similarly-sized ICE vehicles in cost, convenience, and performance.

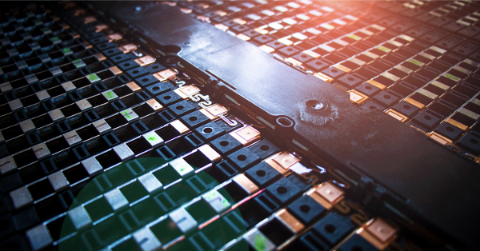

Opportunities for pressure-sensitive tapes and adhesives

As we witness the shift from ICE to EV, the converting and tape industries are well-positioned to grow alongside this revolution. EV batteries present numerous opportunities for pressure-sensitive materials that enhance efficiency, safety, and assembly. These materials are already addressing some of the most challenging issues faced by battery pack manufacturers as they race to improve technology.

We’ve identified several key EV battery applications where pressure-sensitive materials are making a significant impact:

- Cell to Cell Bonding: Provides structural integrity in pouch and prismatic battery cells.

- Thermal Runaway Protection: Prevents thermal runaway events where fires can spread from cell to cell.

- Flexible Busbars: Flexible, printed circuits requiring electrical insulation and flame resistance.

- Thermal Interface Materials (TIMs): Assists with battery module cooling.

- Electrical Insulation: Provides insulation throughout the battery pack.

- Compression Padding: Protects individual cells from damage caused by impact, movement, or swelling.

- Pack Seal and Gasketing: Creates watertight seals between battery casings and rubber gaskets.

These materials offer specific properties, such as dielectric strength, flame retardancy, and bond strength, making them ideal for temperature control, flame barriers, electrical insulation, cushioning, and bonding of battery pack components. Additionally, they are easy to apply, provide a slim profile, and offer a continuous bond across a large surface area—qualities that are crucial as the industry seeks to reduce battery pack and vehicle weight.

The road ahead

Avery Dennison has a long history in the automotive industry. Since our Performance Tapes business unit was established in the 1960s, our Automotive Portfolio has evolved alongside the vehicles themselves. We’ve worked closely with OEMs, tier suppliers, and converters to understand engineering challenges, design requirements, and growth opportunities, collaborating to develop effective and reliable solutions.

As proud as we are of our history, we’re even more excited about the future of the industry. We are committed to leading the way in adopting pressure-sensitive adhesive tapes for EV applications. Our EV Battery Portfolio will continue to grow and evolve alongside industry needs. You can count on Avery Dennison to provide the solutions you need, when you need them.

Learn more about our EV Battery Portfolio at tapes.averydennison.com/evbattery.

About the author

Achim Kappenstein

Director of Energy Storage and Electrification, at Avery Dennison Materials Group EMENA

Achim brings over 20 years of global experience in the automotive industry, having held leadership roles at tier-one suppliers across multiple regions. His expertise includes driving innovation in both the automotive and renewable energy sector.

Achim joined Avery Dennison in 2024, he is responsible for driving the Electrification strategy, to align the company’s capabilities with the evolving needs of the ES industry, ensuring its readiness for future growth, regulations and innovations. Since 2018, Achim has been deeply involved in the Battery Electric Vehicle (BEV) and Renewable Energy industries, contributing to advancements in sustainable technologies. His extensive knowledge positions him as a strategic expert in creating solutions that promote sustainability and circularity.

achim.kappenstein@eu.averydennison.com

www.linkedin.com/in/achim-kappenstein/