Noise, vibration, and harshness (NVH) solutions for automotive powertrains

In today’s automotive industry, driver expectations for quieter, smoother, and more refined vehicles are higher than ever. At Avery Dennison, we provide innovative adhesive and vibration damping tape technologies designed to meet the challenges of noise, vibration and harshness (NVH) in powertrain systems. Our solutions help manufacturers enhance vehicle performance, comfort, and overall driving experience, setting new standards for automotive NVH management. As electric vehicles (EVs) become more common, traditional NVH sources are giving way to new challenges. Our CLD (Constrained Layer Damping) tapes address these needs, quieting lightweight structures, improving acoustic comfort, and aligning with OEM lightweighting strategies.

What Is NVH and why it matters in modern vehicles

NVH stands for Noise, Vibration, and Harshness, a critical trio of factors that influence how drivers and passengers perceive vehicle quality. Understanding NVH meaning is essential for automotive engineers aiming to create quieter, smoother, and more comfortable rides. NVH issues can come from sources, including engine operations, powertrain dynamics, road surfaces, and even aerodynamic flow. Through advanced NVH testing methods such as acoustic profiling, modal analysis, and vibration mapping, manufacturers can pinpoint problem areas and apply targeted solutions. Avery Dennison’s CLD-based damping tapes and automotive adhesives help reduce vibration transmission at the source, providing reliable, long-term NVH control across diverse automotive structures.

NVH testing and analysis

NVH testing identifies the sources and characteristics of noise and vibration through techniques such as:

- Modal analysis

- Acoustic measurements

- On-road simulations

- Component-level testing

At Avery Dennison, we support OEMs and Tier suppliers with NVH challenges by providing data-driven material recommendations. Our adhesives and damping tapes are engineered based on extensive lab testing, application simulations, and customer feedback to deliver proven NVH performance.

With in-house Oberst beam testing facilities compliant with ASTM E756, ISO 6721‑3, and SAE J1637, we offer temperature- and frequency-dependent damping curves that can be integrated directly into NVH simulation models, accelerating approval cycles and cutting validation time by up to 30%.

Tackling noise in NVH automotive applications

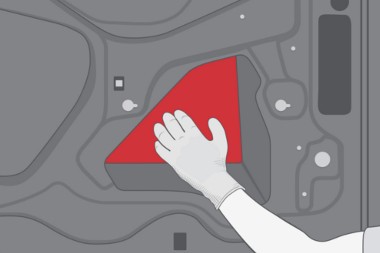

In powertrain systems, noise can come from engine operations, road interactions, or mechanical connections. Reducing noise requires strategic material selection, thoughtful assembly techniques, and advanced adhesive solutions. Avery Dennison CLD tapes are used not only in interiors but also in dash panels, trunk floors, and EV battery enclosures, helping OEMs meet strict European pass-by noise regulations.

Addressing vibration in the automotive NVH landscape

Vibration in vehicles is typically caused by rotating components, road surface irregularities, and powertrain dynamics. Left untreated, vibrations can lead to discomfort, component wear, and structural fatigue. Our NVH damping tape and adhesive technologies are specially designed to manage vibrational energy and reduce its transmission through the vehicle structure. Whether for engine mounts, chassis components, or body panels, our solutions play a vital role in automotive NVH performance. Our solutions are validated to perform under wide temperature swings and repeated fatigue loads.

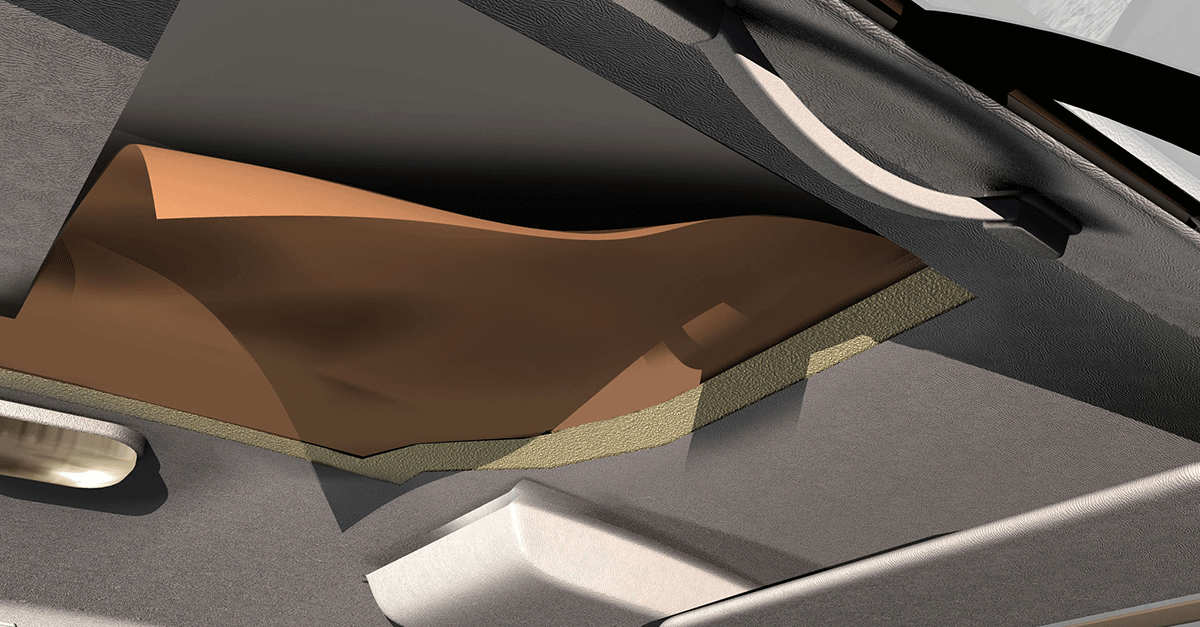

Managing harshness for a smoother ride

Harshness refers to the perception of roughness in a vehicle’s ride quality. It’s not just about sound or movement, it’s about vibrations and shocks. Avery Dennison adhesives and damping tapes help soften harshness at the source, improving ride quality. Our viscoelastic CLD layers are tuned for effective damping over broad temperature and frequency ranges.

Innovation in vibration damping tape and adhesive technology

Our vibration damping tapes are engineered with viscoelastic properties that convert vibrational energy into low-level heat, significantly reducing the transmission of noise and vibration. Coupled with our high-performance adhesives, these tapes bond securely to diverse substrates and support lightweighting initiatives. All solutions are optimized for harsh environments including oil/chemical exposure and elevated operating temperatures, proven in brake shim and powertrain assemblies. Whether you need a solution for bonding, thermal expansion control, or dynamic load damping, Avery Dennison's adhesive technologies are built to perform.

Powertrain NVH analysis for enhanced performance

At Avery Dennison, we work closely with OEMs and Tier suppliers, offering material recommendations. Our Oberst-derived damping curves provide design engineers with immediate input for CAE-based noise prediction, shortening development cycles. With the continued evolution of vehicle design, controlling NVH and delivering optimal noise, vibration and harshness performance remains a key differentiator for automotive brands.

Application summary

Features

- Low and high temperature damping from -10°C to over 110°C

- Pressure-sensitive adhesives engineered for high performance with a wide range of substrates

- Effective solution for bonding needs related to buzz, squeak and rattle issues

- Custom-engineering and tuning to cancel vibrations in a variety of rigid components

- Innovative properties that contribute to improved driving comfort and light-weighting

Benefits

- Bespoke solutions to address noise damping spanning a variety of frequencies

- Customizable noise damping adhesives to provide optimal performance depending on the materials, surfaces and other factors involved

- Sound damping tapes that simultaneously address application and acoustic challenges

- Collaborative opportunities with vehicle engineers to provide customized NVH solutions

Contact us for answers, quotes or samples

We have been a longstanding partner for safety critical systems in the automotive vehicle industry. Partner with Avery Dennison to stay ahead in the automotive market. Our innovative adhesive solutions are tailored to meet your specific needs, ensuring safety, efficiency, and sustainability. Contact us today to learn more about how we can support your NVH, heat shield, or Brakeshim projects.

Whether your application involves bonding rigid metal shields or flexible insulating composites, Avery Dennison provides custom adhesive solutions that fit into various assembly processes.

Michel Ravers

Key Account & Business Development Manager NVH

Michel's career at Avery Dennison, which began in 1990, is defined by his profound expertise in developing adhesives and tapes. His extensive experience, gained through 25 years in R&D and as a technical service leader, has given him an unparalleled understanding of complex challenges, with a special focus on NVH (Noise, Vibration, and Harshness). Michel has transitioned to his current role as Key Account & Business Development Manager, NVH, allowing him to focus his deep expertise on driving innovation and customer solutions in this critical area.