Soft trim bonding

Modern motorists demand premium driving experiences from all new vehicles, and soft trim components are a key part of creating that feeling of quality and comfort. When it comes to these important automotive interior components, manufacturers simply can’t afford to cut corners.

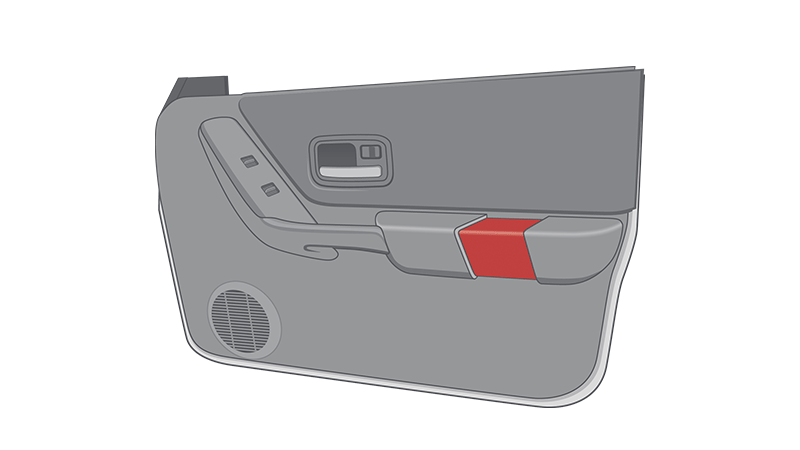

Soft trim bonding and adhesive tapes for automotive interior design

At Avery Dennison, we’re here to support the application and installation of a variety of soft trim components, be they door medallions, armrests, parcel shelves or other features. Using a full line of pressure-sensitive tapes, we’re able to laminate a variety of textiles, leathers and surface covering materials onto foams, soft and hard substrates. From cutting-edge dispersion acrylics and modified acrylics to hot melt rubbers for tough to bond surfaces, our wide range of adhesive technologies guarantees optimal bonding in a variety of soft trim applications for interior car trim and other automotive interior materials.

Avery Dennison PSA's for automotive interiors

Hard to bond to substrates like plastics and painted metals can be bonded by pressure-sensitive adhesives (PSAs) using a combination of the good wetting ability of the adhesive, immediate tack and adhesion, and high bonding surface. Meanwhile, adhesives can offer a wide range when it comes to resistance to temperature, moisture/water, UV, chemicals (often migrating from substrates) and plasticizers.

Specific solutions for specific challenges

Diversity in PSAs also relates to the soft- or hardness, initial tack, resistance to stress & load and shear resistance. This is why Avery Dennison Performance Tapes has 9 different adhesive technologies in our portfolio to meet our customers’ specific needs. This variety is a key enabler in discovering the right automotive interior adhesive for the job. The three adhesive properties that are most useful for characterizing the nature of a PSA are the tack (initial adhesion), the peel adhesion (adhesion), and the shear strength (cohesion). Tack measures an adhesive’s ability to adhere quickly; the adhesion measures the adhesive’s ability to resist removal by peeling, and cohesion measures the adhesive’s ability to remain in position under shearing forces.

Technical highlights of soft trim adhesives

Improve interior air quality

Designed for low VOC emissions, our tapes resist chemicals, plasticizers, and solvents while withstanding extreme temperatures, contributing to healthier indoor environments without compromising durability.

Resources

Andrew Christie

Market Segment Manager Automotive

Andrew Christie is the Business Development Manager responsible for the Automotive Market at Avery Dennison Performance Tapes. He has introduced many innovative solutions to the automotive interior market including lightweight acoustical materials and sustainable seat fabrics. His commitment to the industry continues with delivering pressure-sensitive adhesives that address the challenges facing the automotive industry today.

andrew.christie@eu.averydennison.com

www.linkedin.com/in/andrew-christie