Electric vehicle batteries

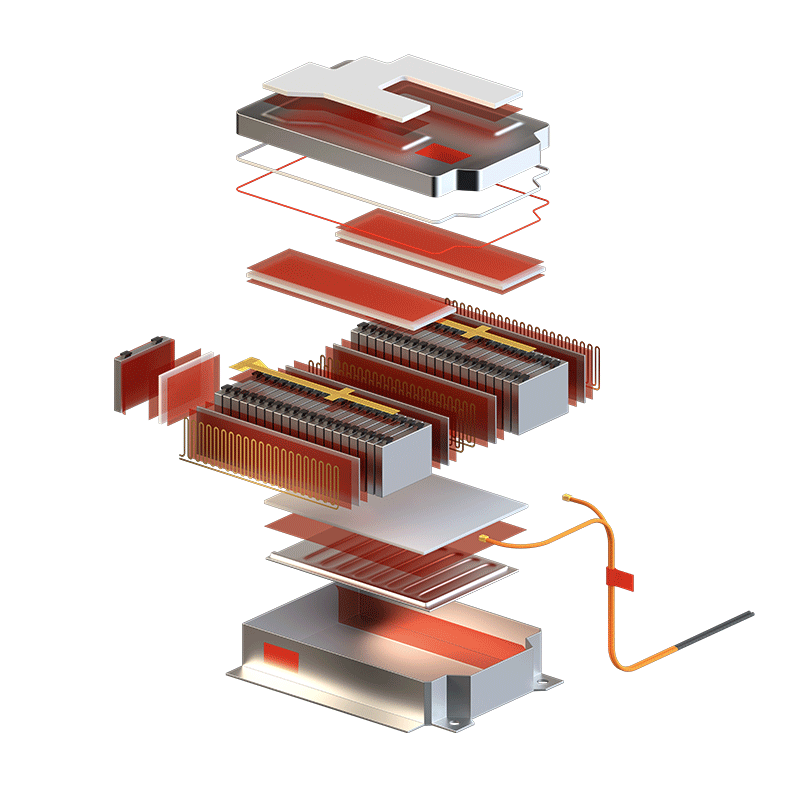

In the rapidly changing world of electric vehicle batteries (EVBs), innovative pressure-sensitive adhesive (PSA) solutions are crucial. Avery Dennison Performance Tapes specializes in cutting-edge PSAs designed to meet the unique demands of EVBs. From ensuring safety and reliability to optimizing performance and facilitating efficient manufacturing, our adhesive technologies empower you to keep pace with market advancements with the utmost confidence.

Our three pillars of excellence

Optimize your EV battery performance and efficiency with our certified, eco-friendly solutions trusted by leading manufacturers. Our three pillars of excellence—innovation, sustainability, and reliability—drive the optimization and efficiency of your electric vehicle batteries.

1. Enhancing safety and reliability

Our adhesives, compliant with the UL® 94 test method for flammability, provide flame-retardant properties, electrical insulation, and thermal runaway protection, ensuring that your battery systems remain secure.

2. Optimizing performance and efficiency

Achieve better performance and efficiency with our bonding technologies that improve heat distribution, reduce weight and facilitate efficient thermal management.

3. Building on these pillars

Our adhesive solutions are designed to excel in key application areas. Enhance safety, reliability, and sustainability in your manufacturing process.

Manufacturing and sustainability

Streamline your manufacturing processes and enhance sustainability with our easy-to-apply adhesive solutions. Designed for automation compatibility and minimal environmental impact, our adhesives support high-volume production and sustainable practices.

Applications

At Avery Dennison Performance Tapes, we focus on three main application areas to support your projects in as innovative a way as possible: Thermal Runaway Protection, Electrical Insulation, and General Bonding. Our advanced adhesive solutions ensure your batteries are safe, efficient, and sustainable.

Sustainability

Sustainability is a growing concern in the automotive industry, and manufacturers are seeking ways to reduce their environmental footprint. As the automotive industry moves towards sustainability, it's essential to minimize the environmental impact of manufacturing processes.

Our adhesive solutions are formulated with eco-friendly materials and manufacturing processes, reducing waste and energy consumption. Additionally, our adhesives enable lightweight designs, contributing to overall vehicle efficiency and reducing carbon emissions during operation. Manufacturers can align with their sustainability goals by choosing Avery Dennison's adhesive solutions while maintaining high-performance standards.

Key features:

Eco-friendly formulations: utilizes renewable and recyclable materials to minimize environmental impact.

Energy-efficient manufacturing: reduces energy consumption during production processes, lowering carbon emissions.

Lightweight designs: contributes to overall vehicle efficiency, reducing energy consumption and greenhouse gas emissions.

Applications:

Battery pack assembly: bonds lightweight components to reduce overall vehicle weight and improve fuel efficiency.

Packaging Optimization: Maximizes space utilization in battery packs, helping to achieve the energy density targets demanded in the industry.

Market segments for automotive adhesives

Contact us for answers, quotes or samples

We have been a longstanding partner for safety critical systems in the automotive vehicle industry. Partner with Avery Dennison to stay ahead in the electric vehicle battery market. Our innovative adhesive solutions are tailored to meet your specific needs, ensuring safety, efficiency, and sustainability. Contact us today to learn more about how we can support your EVB projects.