Thermal runaway protection

Safety is crucial for electric vehicle battery manufacturers as it protects consumers, ensures regulatory compliance, and maintains brand reputation. A strong safety record boosts market competitiveness while prioritizing safety drives innovation, enhancing performance and sustainability. Ultimately, safe batteries safeguard individuals and the environment, and at Avery Dennison, we’re with you on this journey every step of the way. Our technologies help to ensure the safety of your batteries in a number of key ways.

Solutions for thermal runaway prevention

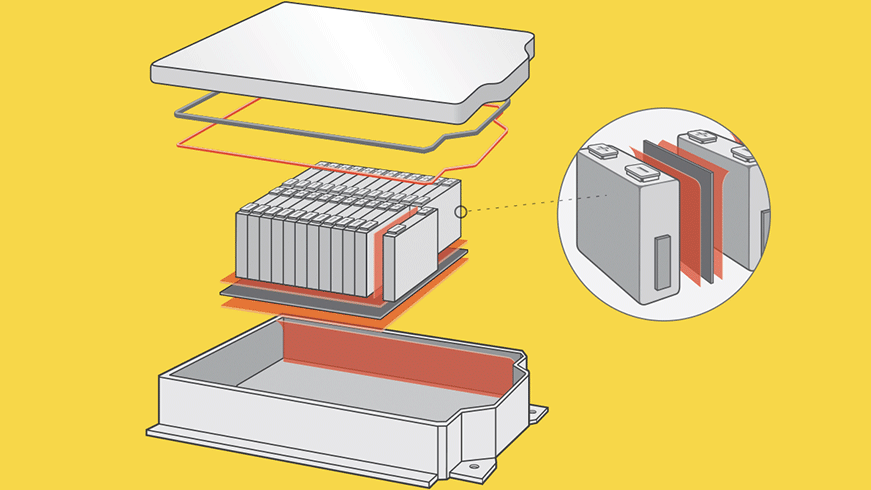

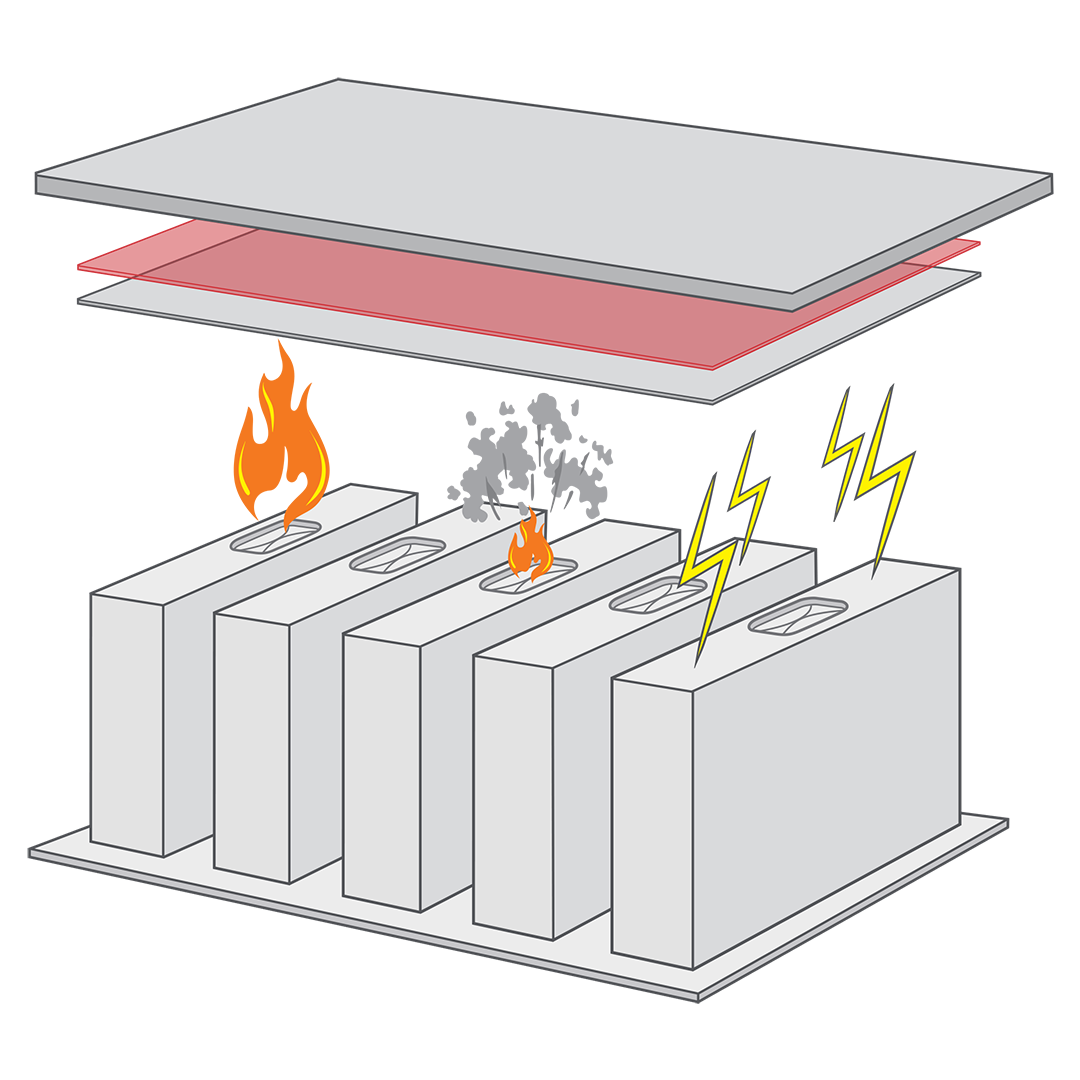

Our adhesives are engineered to help play a role in preventing thermal runaway (TR), a critical safety concern in electric vehicle batteries. Thermal runaway occurs when a battery cell overheats and causes a chain reaction of overheating in adjacent cells, potentially leading to fires or explosions.

To combat this, our solutions for thermal runaway protection integrate seamlessly with materials like mica and ceramic fibers, providing the key layer of defense against thermal events. Additionally, our adhesives can also offer superior flame-retardant properties that meet stringent safety standards such as UL® 94. This ensures that your battery systems remain secure and reliable, even under extreme conditions.

Thermal runaway and propagation is a significant safety hazard for electric vehicle batteries, posing risks of overheating, fires, and explosions. Our adhesives are designed to work with TR barrier solutions to provide an effective barrier against such events, ensuring the highest level of safety.

Wrapping friable, fragile materials

Handling and protecting delicate materials in EV batteries is critical to prevent damage and ensure reliability. Our adhesive solutions offer secure wrapping for fragile materials, maintaining their integrity during manufacturing and operation.

Key features:

Prevent particle shedding: keeps friable materials intact, preventing particles from compromising the performance of other pack materials and components.

Automation-friendly: designed for use with automation systems, ensuring precise and efficient application.

Robust protection: provides a protective barrier around fragile materials, reducing the risk of damage.

Applications:

Material encapsulation: securely wraps delicate materials to protect them during assembly and use.

Automated handling: Allows for efficient handling and placement by automated systems, enhancing productivity.

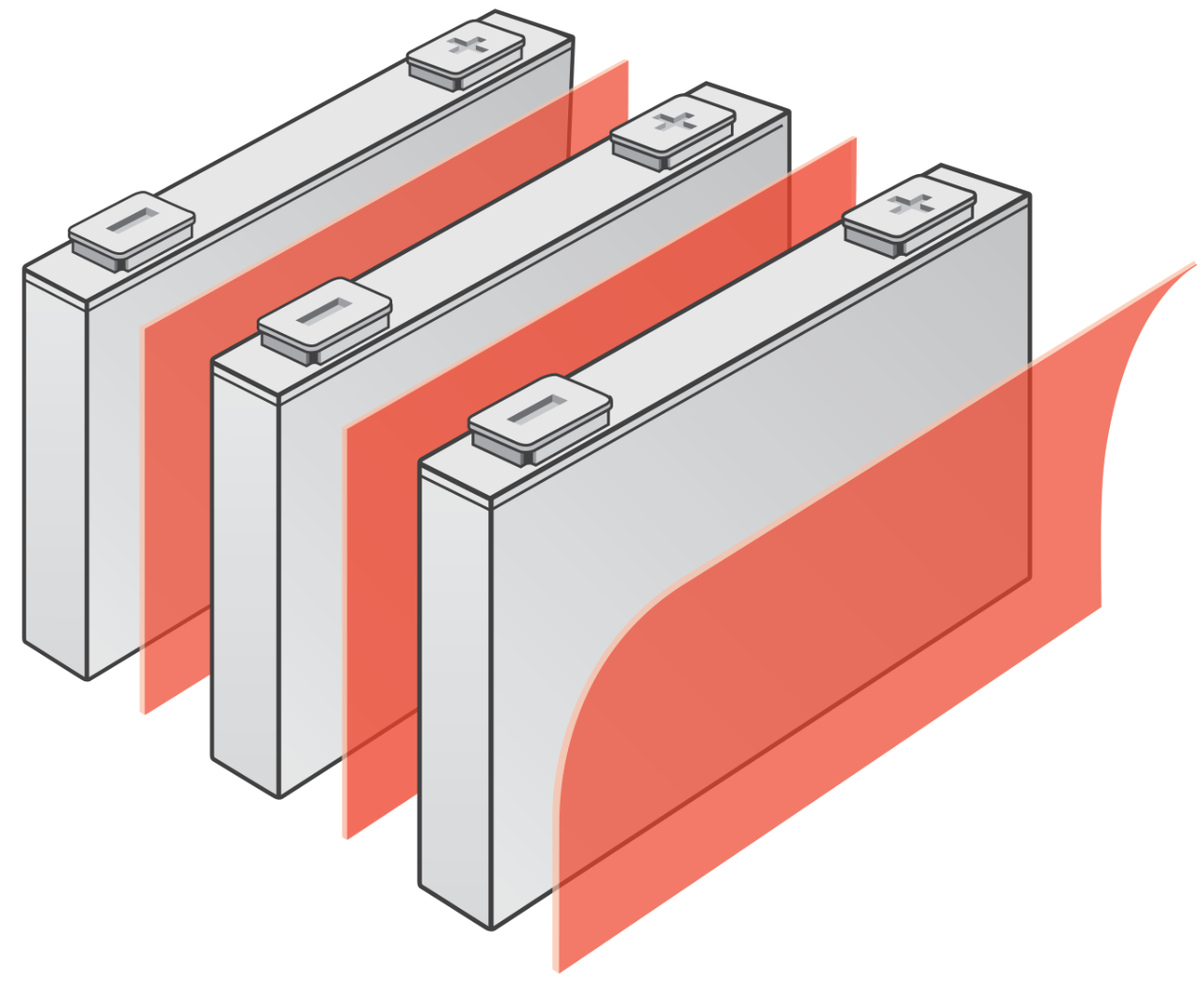

Cell stack assembly

Assembling battery cells into stacks requires robust and reliable bonding solutions. Our adhesives provide strong bonds that maintain structural integrity and allow for automated assembly processes. This not only enhances the efficiency of cell stack assembly but also ensures that the assembled stacks can withstand operational stresses and maintain performance over time.

Building reliable and durable cell stacks is essential for EV battery performance. Our adhesives ensure strong bonds and facilitate efficient automated assembly, enhancing the structural integrity and longevity of cell stacks.

Key features:

Strong bonding: provides robust adhesion to maintain structural integrity under operational stresses.

Automation compatibility: suitable for use with automated assembly lines, improving efficiency and consistency.

Durability: ensures long-lasting bonds that withstand environmental and mechanical stresses.

Applications:

Compression Pad Bonding: bonding compression pads to cells to ease assembly and give the robustness to meet the challenges when operating the vehicle during its lifetime.

Cell-to-Cell Bonding: Bonds individual cells into stable stacks, ensuring reliability and performance.

Module Assembly: Facilitates the assembly of cell modules, enhancing overall battery pack construction.

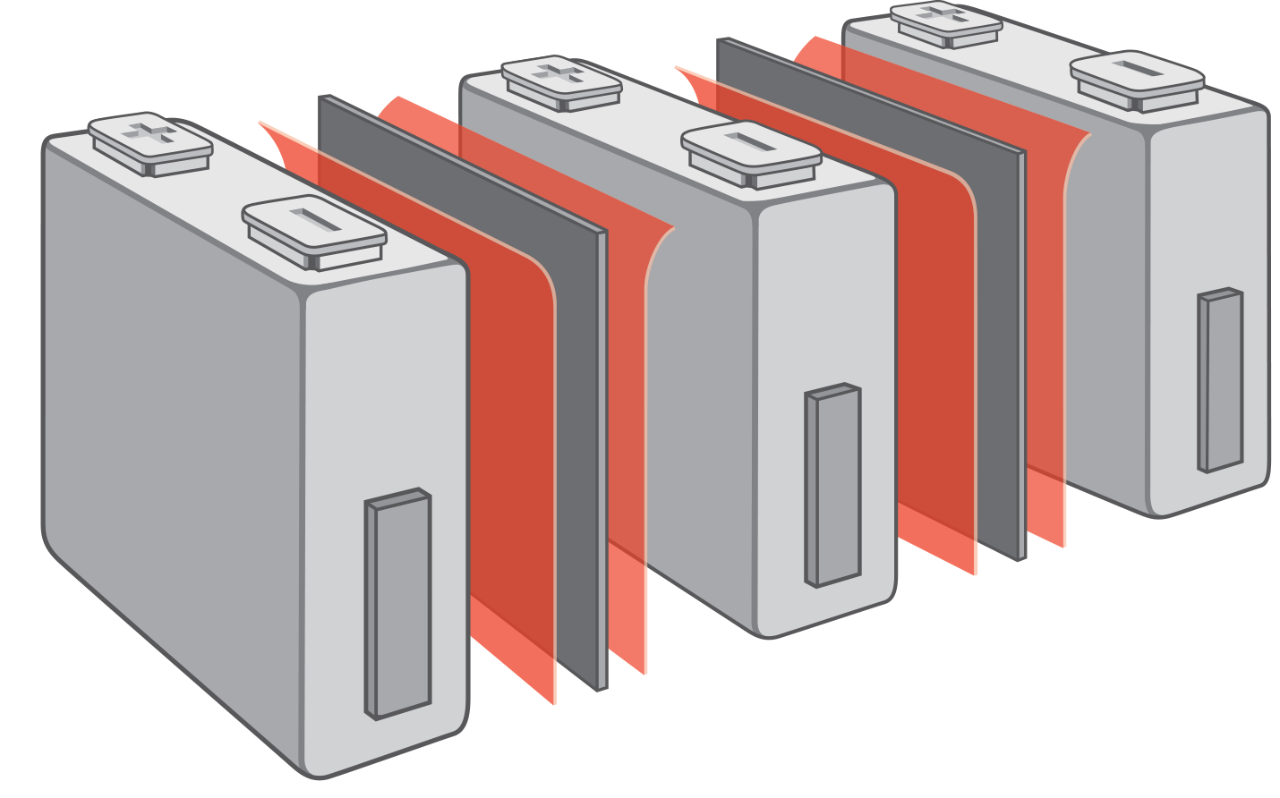

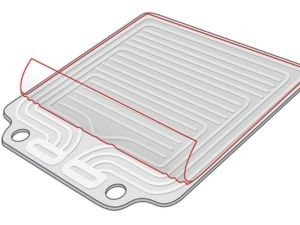

Attaching thermal runaway pads

Thermal runaway pads are essential for mitigating the risk of thermal events in EV batteries. The materials used are often non woven or felted materials, or friable like ceramic aerogels, prone to particle shedding and low cohesive strengths. Our adhesive solutions enable encapsulation and secure attachment of these pads to individual cells , within cell stacks and between modules, ensuring they remain in place throughout the battery's operational life. This contributes to the overall safety and reliability of the battery system. Thermal runaway pads are vital for safety in EV batteries. Our adhesives provide secure attachment, ensuring these pads remain in place and effectively mitigate thermal risks.

Key features:

Secure attachment: ensures thermal runaway pads are firmly bonded to cells and stacks.

High reliability: maintains adhesion under various operational conditions, providing consistent protection.

Safety compliance: meets industry standards for thermal protection, enhancing overall battery safety.

Applications:

Cell Protection: Bonds thermal runaway pads to individual cells, preventing thermal events.

Stack Integration: Integrates thermal protection within cell stacks, ensuring comprehensive safety.

Bonding thermal management materials within and outside the battery pack.

Contact us for answers, quotes or samples

We have been a longstanding partner for safety critical systems in the automotive vehicle industry. Partner with Avery Dennison to stay ahead in the electric vehicle battery market. Our innovative adhesive solutions are tailored to meet your specific needs, ensuring safety, efficiency, and sustainability. Contact us today to learn more about how we can support your EVB projects.