Feature: as automobiles turn up the heat, performance adhesives shine

How converters can grow their business with automotive heat shielding tapes.

You know the saying: “They don’t make ‘em like they used to.” That is certainly the case with automotive design. Today’s cars are lighter and more efficient. Their powertrains are becoming electrified and increasingly computerized. They’re designed to be driven longer and harder than ever before.

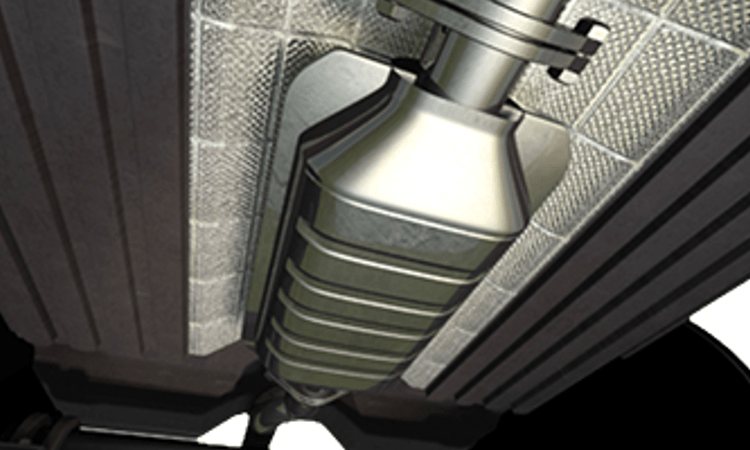

These trends are producing better vehicles, along with a new engineering challenge for OEMs: heat management. Components such as batteries, electronics, motors, and internal combustion turbochargers generate a lot of heat. Cramped engine compartments — filled with an increasing amount of sensitive electronics, and low-melting-point plastics and composites — often do not allow that heat to easily dissipate.

It’s a challenge that the traditional, mechanically fastened, metal heat shield is often no longer suited for. In response, many OEMs are specifying and relying on an evolved heat shield design incorporating pressure-sensitive adhesives.

Dissecting the modern heat shield

Unlike their bolt-on predecessors, modern heat shields consist of three layers: a thin sheet of aluminum or a layer of nonwoven material, and a pressure-sensitive adhesive. Such a design offers a range of advantages.

It can easily be configured to shield a component, even in a tight spot. With the proper adhesive, it can be applied directly to low surface energy (LSE) plastics and other challenging substrates.

It eliminates the need for screws and fasteners, and thus eliminates the need for attachment points. This simplifies engineering and assembly, and cuts costs.

It can help reduce the amount of buzz, squeak, and rattle in a vehicle, contributing to improved NVH (Noise, Vibration and Harshness) performance.

It allows for easier installation, and installation at almost any point in the assembly chain (from tier supplier to final assembly line).

How converters are seizing the opportunity with heat shield tape

A 2019 report by MarketsandMarkets projects a heat shield market CAGR of 2.6% through 2027. Much of that growth will be propelled by the development of new heat shield technology.

So as more OEMs specify these heat shield constructions, tape converters and tiers are making inroads in the market. They are sourcing the aluminum and nonwoven materials, and combining them with high-performance adhesive solutions. Many rely on the Avery Dennison Performance Tapes portfolio for the adhesives.

The need for high-temperature adhesives

In heat shielding applications, adhesives need to perform while regularly being subjected to temperatures of up to 300 degrees C. They need to conform to unique shapes, including LSE surfaces, with high tack and no lift. They need to maintain durability, even after years of exposure to fuels and chemicals, salt and road grime, and other environmental challenges.

Avery Dennison pressure-sensitive solutions have been used in heat shielding applications for nearly two decades. Those solutions draw from our broader portfolio of performance products. This includes adhesives such as our General Purpose Acrylic, LSE Acrylic, and Low VOC Acrylic. All are proven for heat shielding applications and meet many OEM specifications.

Let us help you grow your business in automotive

Modern heat shields have come a long way — they certainly do not make ‘em like they used to. That just might be an opportunity for you to grow your business in the automotive segment.

To learn more about our heat shield adhesive solutions, and opportunities with this application, contact your Avery Dennison account manager, or visit heatshield.

About the author

Jarne Machiels

Application & Technical Service Engineer

Jarne Machiels is the Application & Technical Service Engineer responsible for Germany as well as (Automotive) Electronics Market at Avery Dennison Performance Tapes Europe. Thanks to his previouses roles in the printing - and adhesive tape converting industry, he has an extensive know-how to understand your technical needs for each application. In parallel, Jarne focuses on technical innovation within Avery Dennison - being expertised in (printed) electronics, heating applications and automotive safety systems.

jarne.machiels@eu.averydennison.com

www.linkedIn.com/in/jarne-machiels