Adhesive solutions for heat shield applications

Modern vehicles are pushing the limits of performance, efficiency and design, and with that comes increased thermal stress. Avery Dennison delivers innovative adhesive solutions that improve the function and durability of heat shields. We help OEMs and Tier suppliers to manage extreme temperatures and improve system integrity, safety and overall vehicle performance.

The role of heat shields in powertrain systems

Heat shields are essential in protecting sensitive vehicle components from thermal loads generated by engines, exhaust systems, and electrified powertrain elements. They help preserve material integrity and improve thermal management. Adhesives play a critical role in bonding these shields to a range of substrates while withstanding exposure to high temperatures, vibration, and chemicals.

Challenges in automotive heat shield bonding

Heat shield adhesives must perform under conditions like extreme heat, rapid thermal cycling and exposure to fuels. At the same time, they must bond reliably to materials like aluminum, stainless steel, and composite substrates.

Avery Dennison’s high-performance adhesive tapes are designed to meet these challenges, enabling manufacturers to:

- Improve thermal isolation without adding weight

- Bond heat shields in tight, contoured areas

- Streamline production with die-cuttable, easy-to-apply materials

- Maintain performance across wide temperature ranges

- Replace mechanical fasteners for quieter, cleaner assemblies

Engineered adhesive technologies for thermal protection

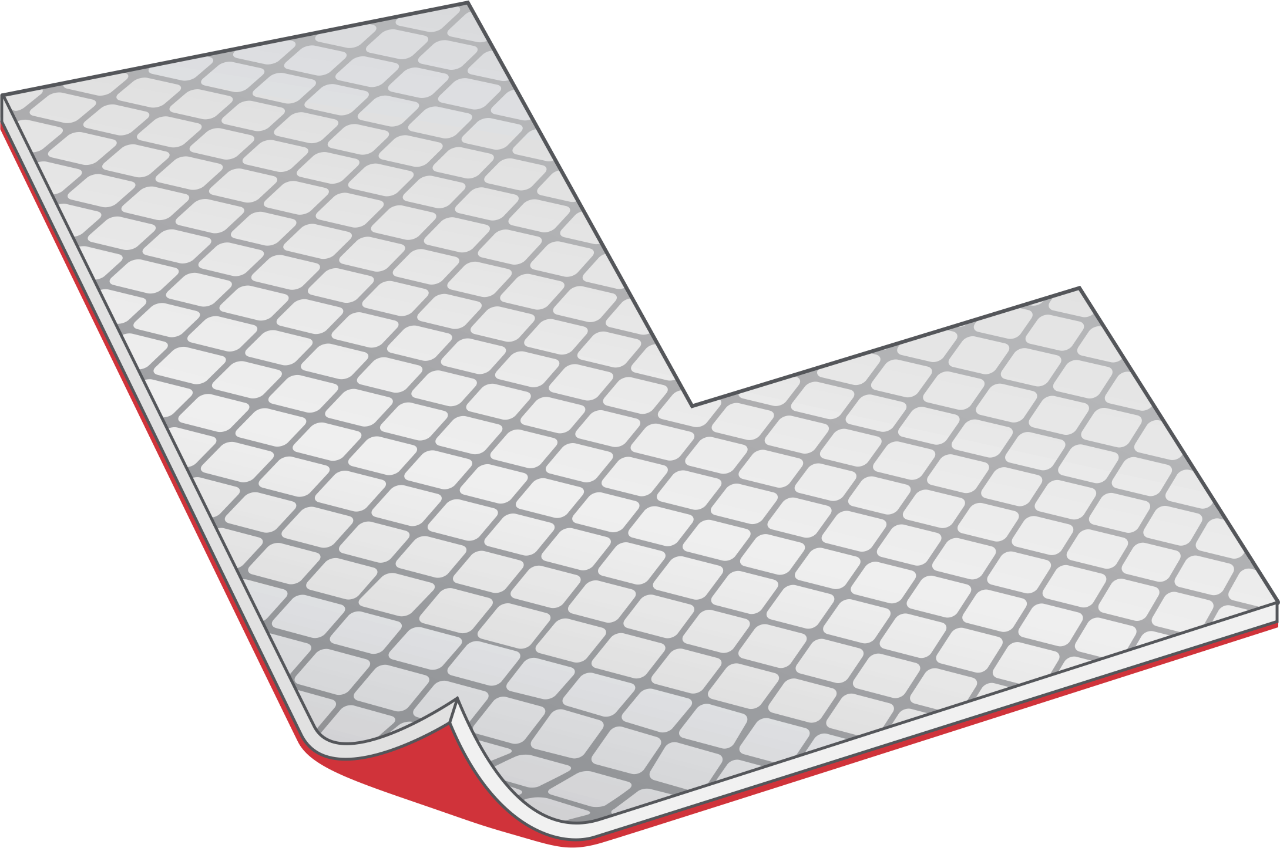

Our portfolio includes pressure-sensitive adhesives (PSAs) and thermal-resistant bonding tapes that offer good adhesion, even in temperatures exceeding 200°C. With high tack, long-term durability and chemical resistance, these materials simplify the attachment of aluminum or foil-backed shields across various zones in the powertrain.

For electric vehicles, where battery systems demand thermal containment, our heat shield adhesives support evolving designs while meeting automotive safety and environmental standards.

Application summary

Features

- An extensive portfolio that includes solutions for LSE substrates, all available in wide web format

- High temperature performance to work with shielding capable of heat reduction from 330°C to 60°C

- Selected liners for high tear resistance and seamless application

- Secure and long-lasting bonding, even when exposed to the harsh conditions within the vehicle such as automotive fluids and heat

Benefits

- Effective heat protection for heat sensitive components and plastics

- Variable characteristics, capable of laminating heat shield layers together or alternatively mounting heat shield to car components

- Excellent adhesion to glass fiber and other complex surfaces

- Reduced assembly time and chance of injury compared to mechanically attached shields

- Easy to apply through easy-to-use (peel off) liners

- Available in various constructions, suitable for laminating onto polyester or glass fiber felts during manufacturing

Contact us for answers, quotes or samples

We have been a longstanding partner for safety critical systems in the automotive vehicle industry. Partner with Avery Dennison to stay ahead in the automotive market. Our innovative adhesive solutions are tailored to meet your specific needs, ensuring safety, efficiency, and sustainability. Contact us today to learn more about how we can support your NVH, Brakeshim and heat shield projects.

Whether your application involves bonding rigid metal shields or flexible insulating composites, Avery Dennison provides custom adhesive solutions that fit into various assembly processes.

Michel Ravers

Key Account & Business Development Manager NVH

Michel's career at Avery Dennison, which began in 1990, is defined by his profound expertise in developing adhesives and tapes. His extensive experience, gained through 25 years in R&D and as a technical service leader, has given him an unparalleled understanding of complex challenges, with a special focus on NVH (Noise, Vibration, and Harshness). Michel has transitioned to his current role as Key Account & Business Development Manager, NVH, allowing him to focus his deep expertise on driving innovation and customer solutions in this critical area.