High-performance adhesive solutions for brake shim applications

Brake noise is one of the most common sources of driver dissatisfaction. At Avery Dennison, we engineer advanced adhesive technologies to support brake shim performance, reduce noise, and ensure a more refined and reliable braking experience. Our adhesive and damping tape solutions are designed to meet the demands of modern braking systems, offering high bonding strength, thermal resistance, and excellent noise reduction under extreme conditions.

Why brake shim adhesives matter

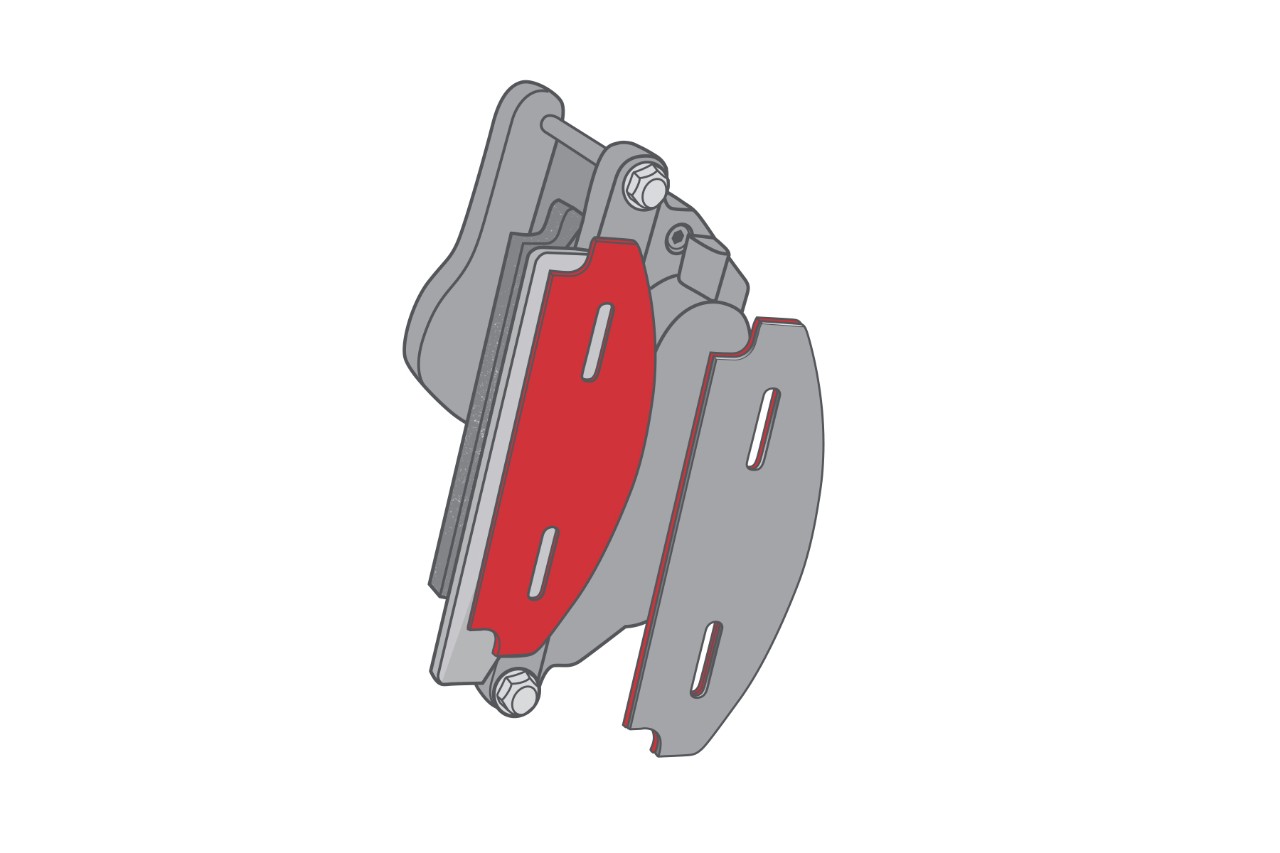

Brake shims act as a critical barrier between the brake pad and caliper, absorbing and damping vibration to minimize squeal and judder. As braking systems continue to evolve, especially in electric vehicles where brake noise is more noticeable, shims must deliver more than ever before. The right adhesive ensures that the shim stays firmly in place, even under high pressure, repeated thermal cycling, and exposure to moisture and chemicals.

The role of adhesives in brake shim performance

Our high-performance adhesives are developed for brake shim applications, delivering strong initial tack, excellent shear strength and long-term durability across a variety of substrates including steel, aluminum and composite materials. Our adhesive solutions help:

- Eliminate brake squeal and vibration

- Enhance acoustic control and thermal stability

- Withstand exposure to oils, road salts, and heat

- Support automated application processes with consistent results

Advanced tape technologies for brake noise reduction

Avery Dennison’s vibration damping tapes and adhesive solutions are engineered to absorb energy and reduce NVH (Noise, Vibration, and Harshness). These solutions not only reduce brake noise but also extend the life of components by minimizing mechanical stress.

Our formulations are tested to meet automotive standards and adapted to both traditional and electric vehicle platforms. With good temperature resistance and robust environmental durability, our adhesives help OEMs and suppliers meet customer expectations for performance, safety, and comfort.

Flexible support for brake system manufacturers

Whether you're designing electric braking systems or improving acoustic performance in combustion-engine platforms, Avery Dennison works alongside your engineering team to tailor the ideal bonding solution. We combine technical expertise, regional support and a global innovation network to ensure your solution is delivered efficiently.

Application summary

Features

- Proprietary acrylic- and silicone-based adhesives that meet OEM and aftermarket damping requirements

- Bespoke release liners for easy removal at point of application

- Optimized for resistance and longevity to ensure sustained performance over time

- Viscoelastic responsiveness to ensure damping under targeted conditions

- Engineered through cutting-edge R&D that contributes to system damping behavior

Benefits

- Customizable solutions to achieve desired properties for variable frequency and temperature ranges

- Customizable with logos and colors to support automated optical recognition manufacturing processes

- High temperature damping up to 250°C and low temperature down to -5 °C

- Tailoring capabilities to allow for ease of conversion, lamination, stamping and liner removal

- Contributes to the quiet ride that OEMs and their customers demand

Contact us for answers, quotes or samples

We have been a longstanding partner for safety critical systems in the automotive vehicle industry. Partner with Avery Dennison to stay ahead in the market. Our innovative adhesive solutions are tailored to meet your specific needs, ensuring safety, efficiency, and sustainability. Contact us today to learn more about how we can support your NVH, brake shim and heatshield projects.

Michel Ravers

Key Account & Business Development Manager NVH

Michel's career at Avery Dennison, which began in 1990, is defined by his profound expertise in developing adhesives and tapes. His extensive experience, gained through 25 years in R&D and as a technical service leader, has given him an unparalleled understanding of complex challenges, with a special focus on NVH (Noise, Vibration, and Harshness). Michel has transitioned to his current role as Key Account & Business Development Manager, NVH, allowing him to focus his deep expertise on driving innovation and customer solutions in this critical area.