Automotive tapes for seat heating components

As vehicle interiors evolve to deliver greater comfort and efficiency, automotive seat heating systems have become a standard feature across many vehicle segments. These systems rely on adhesive solutions that can securely bond heating and sensing components to seat structures while maintaining comfort, durability, and long-term performance. Avery Dennison provides high-performance adhesive tapes for seat heating applications that meet OEM requirements and support reliable electronics assembly throughout the vehicle lifecycle.

Adhesives engineered for extended vehicle lifetimes

Modern vehicles are designed to remain in service longer and operate under increasingly demanding conditions. Extended platform lifetimes, higher vehicle utilization, and the growth of ride sharing place greater stress on interior components, including seat heating systems. At the same time, manufacturers continue to seek solutions that help manage weight, improve efficiency, and streamline assembly processes.

Pressure-sensitive adhesive tapes play a critical role in addressing these challenges. Avery Dennison seat heating adhesives are engineered to perform consistently across temperature variations, exposure to moisture such as perspiration, and contact with chemicals commonly found in automotive interiors. These electronic-grade adhesive solutions are designed to maintain secure bonding throughout the vehicle’s service life without compromising seating comfort or system performance.

Performance tapes for seat heating and occupant sensing

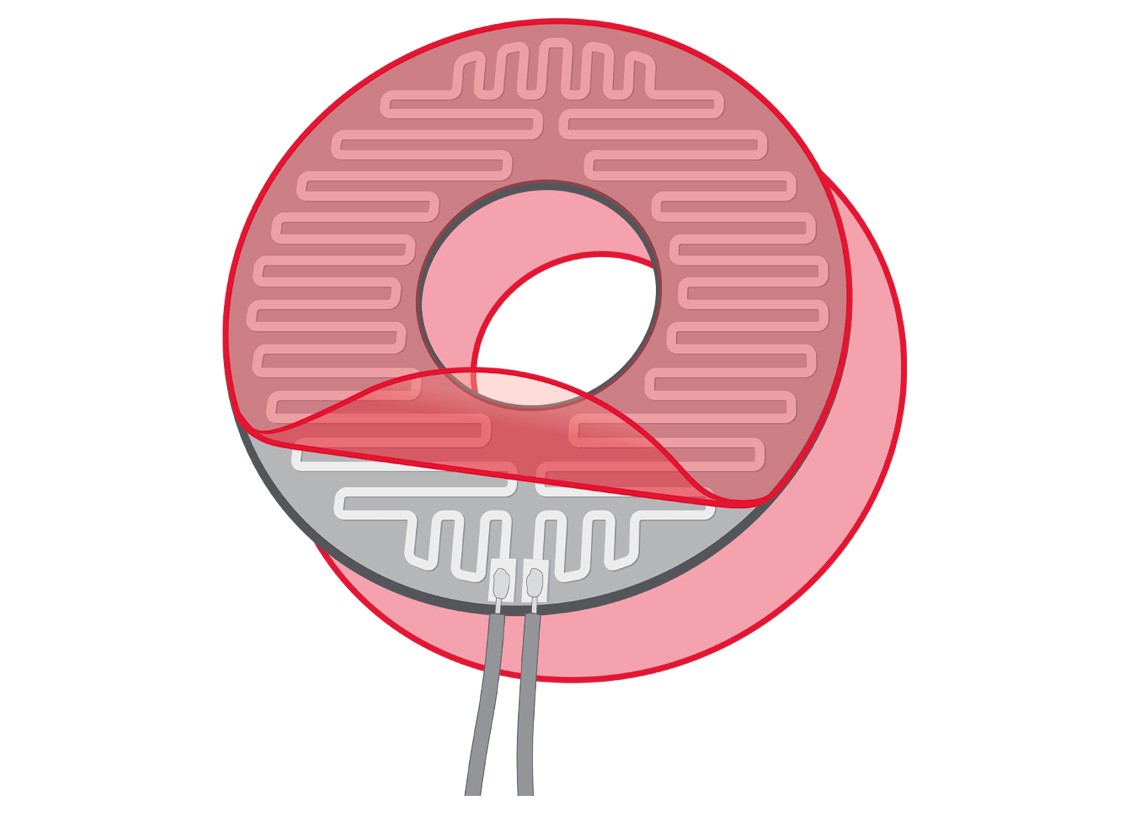

Seat heating systems and occupant sensors are typically integrated directly into seat foam assemblies. Avery Dennison adhesive tapes can be die-cut and laminated to heating or sensing components before being delivered to seat manufacturers for final assembly. This approach supports efficient, repeatable production while ensuring precise placement of electronic elements.

Our portfolio includes acrylic and rubber-based adhesive technologies engineered to bond heating and sensing layers to a wide range of materials, including PU, PE, and EPDM foams, as well as non-woven webs and scrims. These adhesives offer durable bonds that remain stable under thermal cycling and mechanical stress, supporting consistent system performance over time.

Why pressure-sensitive adhesive tapes for seat heating applications?

Compared with mechanical fastening or wet adhesive systems, pressure-sensitive tapes offer clear advantages for seat heating assembly and electronics integration.

Properties and benefits of adhesive tapes for seat heating

- Secure bonding of heating and sensing layers to automotive seat foams

- Resistance to temperature differences, moisture, and chemicals

- Durable adhesion that does not affect seat comfort or cushioning

- Compatibility with printed heating elements and conductive ink circuits

- Reduced assembly time and improved manufacturing flexibility

- Easy application with controlled liner release to support operator efficiency

- Low-VOC solutions available to support interior air quality requirements

- Designs compatible with ventilated seating systems

These benefits make Avery Dennison adhesives a reliable choice for automotive seat manufacturers facing increasing productivity and performance demands.

Adhesive technologies tailored to seat heating design

Avery Dennison offers a broad range of adhesive constructions to support different seat heating and occupant sensing requirements. Solutions include UV-cured acrylic adhesives for strong bonding to polyurethane foams with low emissions, dispersion acrylics that balance foam compatibility with low odor values, and rubber-based pressure-sensitive adhesives designed for challenging foam surfaces and mold release conditions.

These adhesive technologies can be supplied as transfer tapes or reinforced constructions with scrims or carriers, supporting pattern coating and selective adhesive placement where required. This flexibility allows manufacturers to optimize both performance and material efficiency without modifying existing foaming or assembly processes.

Contact us for answers, quotes or samples

Avery Dennison works closely with OEMs and seat manufacturers to support the development of reliable, efficient seat heating systems. Our adhesive solutions are engineered to deliver durable bonding and consistent performance throughout the vehicle lifecycle, helping streamline assembly while maintaining comfort and functional integrity.

As part of our broader Automotive Electronics portfolio, Avery Dennison also supports Steering Wheel and Wire Harness applications, enabling secure bonding and long-term reliability across interconnected vehicle systems.