Indoor Air Quality (IAQ) and the importance of low VOC products

From automotive to building and construction, the materials used in many industries can release potentially harmful pollutants – VOCs – that lead to short- and long-term health problems. Here, we discuss the benefits and importance of high-performance, low VOC tapes.

The risk of poor IAQ

While there is often concern regarding air pollution outdoors, the majority (four million) of the seven million deaths linked to air pollution are in fact caused by indoor air pollution. Indeed, between our homes, schools, offices, cars and public buildings, the US Environmental Protection Agency has shown that we typically spend 90% of our time indoors, where the concentrations of potentially harmful pollutants are often two to five times higher than typical outdoor concentrations.

This is where the concept of ‘sick building syndrome’ (SBS) stems from – used to describe situations where people experience negative health effects from spending time in a home or building.

Volatile organic compounds (VOCs)

Many of the adverse effects of indoor air pollution and poor indoor air quality (IAQ) are caused by volatile organic compounds (VOCs). VOCs are both man-made and naturally occurring organic chemicals that evaporate at low ambient room temperature and are easily dispersed into the surrounding air, many of which can be harmful to humans. Examples include ammonia and formaldehyde. Given the impacts, and the amount of time we spend inside, it is important to reduce the presence of VOCs in indoor environments wherever possible.

There are multiple ways to achieve this. Increasing ventilation can allow VOCs to disperse, while lowering humidity and temperatures can ensure a reduction in the number of VOCs emitted by building materials such as wood, paints, and adhesives. At Avery Dennison, however, we take this one step further, working to eliminate VOCs as far as possible by ensuring all our products emit as few VOCs as possible.

Achieving low VOC levels

To achieve low VOC, we consider some of the main factors that contribute to the presence of such compounds, including the composition of materials, production process and transportation of materials. Critically, this needs to be done while maintaining product performance. To strike the ideal balance, our research and development department continually performs rigorous tests, exploring the various options available.

Balancing performance and VOC reduction

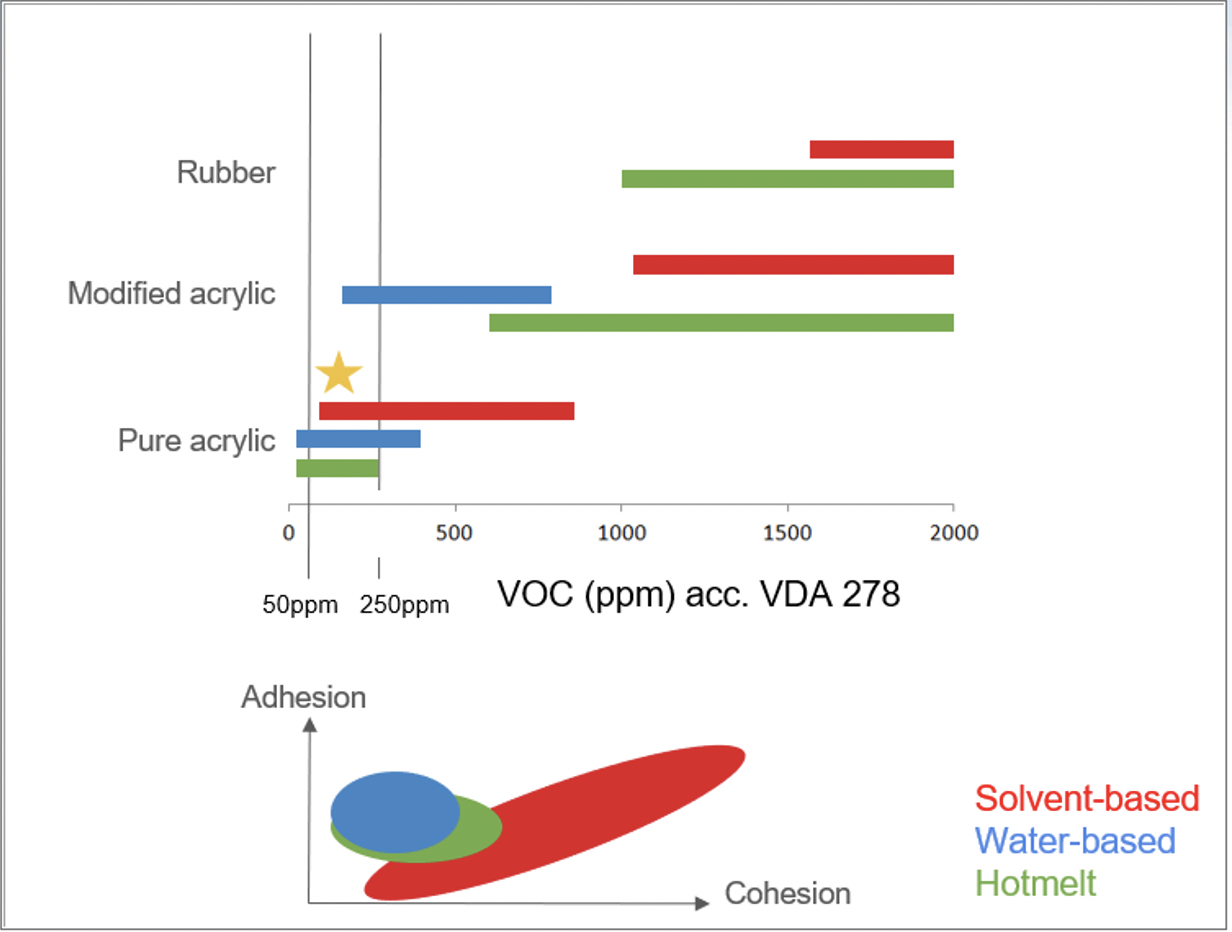

As an example, while rubber tapes and modified acrylic adhesives perform well, they are higher in VOCs. As a result, we use pure acrylics to reduce the impact of chemistry on the release of VOCs, while still ensuring our products work as effectively as possible. This is why we often use pure acrylic adhesives based on emulsion in our products made for the building and construction industry, capable of bonding to a range of metals, plastics, woods and other commonly used materials.

Contact us for answers, quotes or samples

We have been a longstanding partner for safety-critical systems in the building and construction industry. Partner with Avery Dennison to stay ahead in this competitive market. Our innovative adhesive solutions are tailored to meet the unique needs of construction, ensuring durability, efficiency, and sustainability. Contact us today to learn more about how we can support your next project.

Quin Dams

Market Segment Manager Building & Construction / General Industrial

Quin is passionate about technical building applications since he designed and built his family home back in 2012.

Professionally, Quin held several positions as Product Manager responsible for the product life cycle of many technical applications related to the building environment, namely in adhesives, lighting and plastics.

He joined Performance Tapes Europe as a Market Segment Manager for tape applications in the construction and industrial markets where he teams up with customers and R&D to achieve tape solutions that improve the installation of buildings and related products and processes.

quin.dams@eu.averydennison.com

www.linkedin.com/in/quin-dams