Bonding Study: Superior Felt & Filtration Sunburst 1000 Felt Series

Determining the correct adhesive when bonding to foam and felt may be challenging, especially when seeking to provide your customer an accurate quote quickly and accurately. To help you with the adhesive selection, and the technical requirements your customer may require, Avery Dennison Performance Tapes has developed a series of adhesive technology bonding studies. These studies highlight the performance of our Core Series™ Portfolio adhesive products when combined with foams and felts from national manufacturers.

Bonding to Sunburst 1000 Felt Series

Manufactured by Superior Felt & Filtration, the Sunburst 1000 Felt Series is an earth-friendly, 100% synthetic, needle punched felt used in automotive trim and aftermarket products. It is suited for applications such as seating, headliners, gaskets, anti-squeak / anti-rattle (NVH) and other interior components. In addition to automotive, Sunburst 1000 Felt Series products may also be used for applications in appliances, aerospace, electronics, filtration, light and heavy industrial, and for creating decorative spaces.

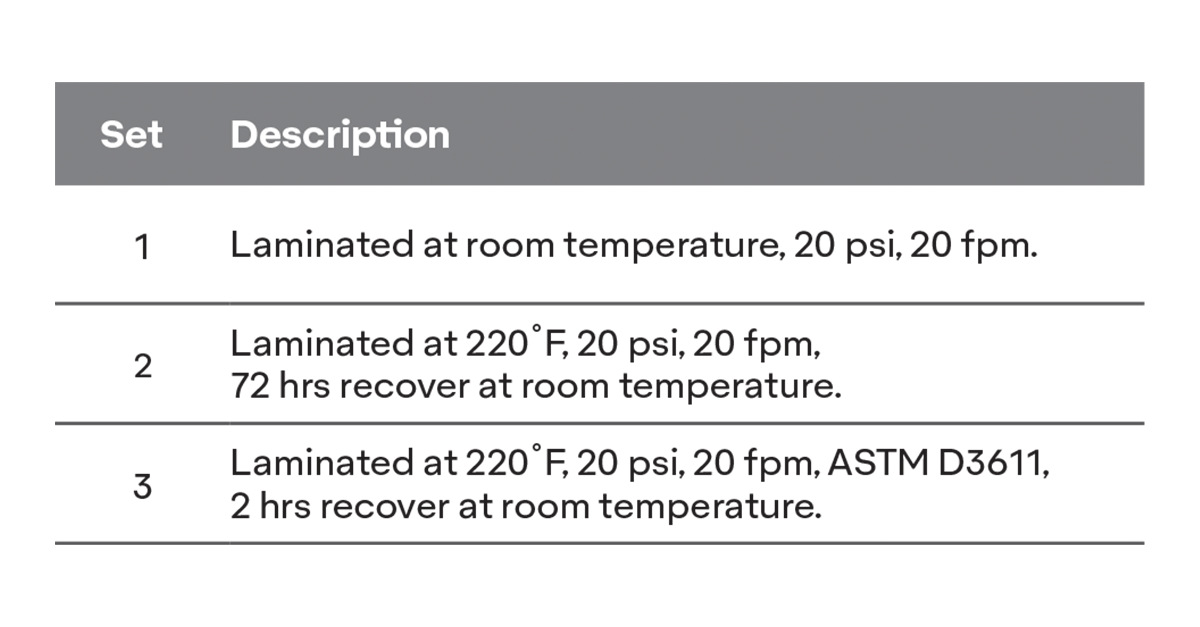

Sunburst Felt and Avery Dennison Adhesive Sample Preparation

The Innovation Center is also where we perform value-added lab services in support of specific customer requests. If an Avery Dennison adhesive product is not currently certified for a particular OEM specification, for instance, the lab can do that certification work at no extra cost to the customer. That means there’s no need for the customer to incur the expense and delay of working with a third-party laboratory.

Sunburst Felt and Avery Dennison Adhesive Sample Testing

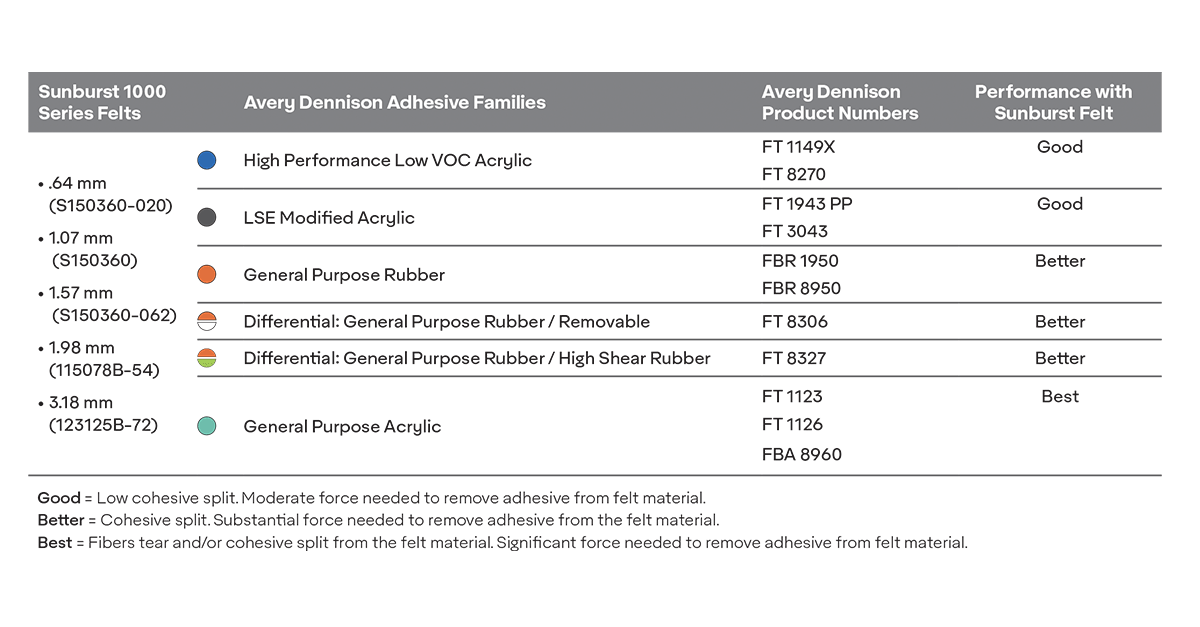

Felt bonding is affected by the felt’s thickness and integrity. Adhesion to felt is impacted by factors, such as: adhesive mass, pressure, lamination speed and temperature. The three samples were tested at 180° Peel Adhesion at 12 in/min. It was determined by this study that heat lamination is beneficial.

To identify the Avery Dennison Core Series adhesive ideal for your application, please refer to the Core Series Product Selection Tool. Using the Core Series' simple four-step adhesive selection process, you will be able to find the product that best suits your needs. The Core Series Product Selection Tool is available at the Avery Dennison Core Series.

About the author

Quin Dams

Market Segment Manager Building & Construction / General Industrial

Quin is passionate about technical building applications since he designed and built his family home back in 2012.

Professionally, Quin held several positions as Product Manager responsible for the product life cycle of many technical applications related to the building environment, namely in adhesives, lighting and plastics.

He joined Performance Tapes Europe as a Market Segment Manager for tape applications in the construction and industrial markets where he teams up with customers and R&D to achieve tape solutions that improve the installation of buildings and related products and processes.

quin.dams@eu.averydennison.com

www.linkedin.com/in/quin-dams