Bonding study: Armacell Component Foams

Bonding to Armacell Component Foams

Armacell’s Component Foam division is a proven leader and innovator in expanded foams. The division delivers decades of product knowledge and innovation to its partners in the aerospace, automotive, building/construction, industrial, medical, packaging and sport/leisure segments. Its product lines consist of elastomeric and polyolefin materials produced in bun, sheet and roll form as well as extruded tubes and profiles. Armacell Component Foams' innovative products are engineered for their customers' success.

Elastomeric Foam

Elastomeric Component Foam (ECF) products are high-performance foam formulations that meet stringent physical and chemical property requirements. Armacell's ECF brands include ArmaSound®, ArmaSport®, EnsoLine®, EnsoLite®, and Monarch®. It offers hundreds of expanded rubber products used extensively in industrial, transportation, building/construction and sport/recreational applications. Sixty years of foam innovation enables us to design optimized cell structures and densities for specific physical properties — custom engineered to customer needs.

Polyolefin Foam

Polyolefin Component Foams (PCF) are made from thermoplastic polymers. Armacell's PCF brands include OleCell® and OleTex®. The company makes chemically cross-linked polyethylene in rolls or blocks called “buns” in formulations that vary from soft and flexible to stronger, stiffer specifications. Non-cross-linked polyethylene can be extruded into customizable profile shapes and can be used for thermoforming applications.

Armacell component toams and Avery Dennison adhesive sample preparation

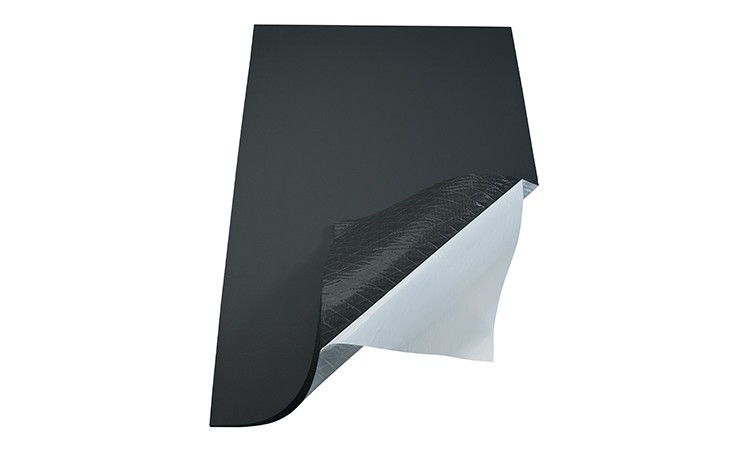

Avery Dennison adhesive products were backed with a 2 mil PET film and trimmed to a one-inch width. Two sample sets were laminated to Armacell Component Foams.

Armacell Component Foams and Avery Dennison adhesive sample testing

Foam bonding is affected by the foam's base polymer, thickness, and cell type. Adhesion to foam is impacted by factors such as: adhesive mass, pressure, compression, lamination speed and temperature. All samples were tested at 180° Peel Adhesion at 12 in/min. It was determined by this study that heat lamination is beneficial (220˚F).

To identify the Avery Dennison Core Series adhesive ideal for your application, please refer to the Core Series Product Selection Tool. Using the Core Series' simple four-step adhesive selection process, you will be able to find the product that best suits your needs. The Core Series Product Selection Tool is available at tapes.averydennison.com/coreseries.

About the author

Quin Dams

Market Segment Manager Building & Construction / General Industrial

Quin is passionate about technical building applications since he designed and built his family home back in 2012.

Professionally, Quin held several positions as Product Manager responsible for the product life cycle of many technical applications related to the building environment, namely in adhesives, lighting and plastics.

He joined Performance Tapes Europe as a Market Segment Manager for tape applications in the construction and industrial markets where he teams up with customers and R&D to achieve tape solutions that improve the installation of buildings and related products and processes.

quin.dams@eu.averydennison.com

www.linkedin.com/in/quin-dams