Adhesive tape solutions for EV battery packs

Avery Dennison offers a portfolio of pressure-sensitive tape solutions for EV battery packs. Avery Dennison EV battery adhesive tape solutions can help you stay in step with this ever-changing EV landscape. We offer adhesive technologies that help pack manufacturers and OEMs reduce flammability, boost dielectric strength and optimize assembly.

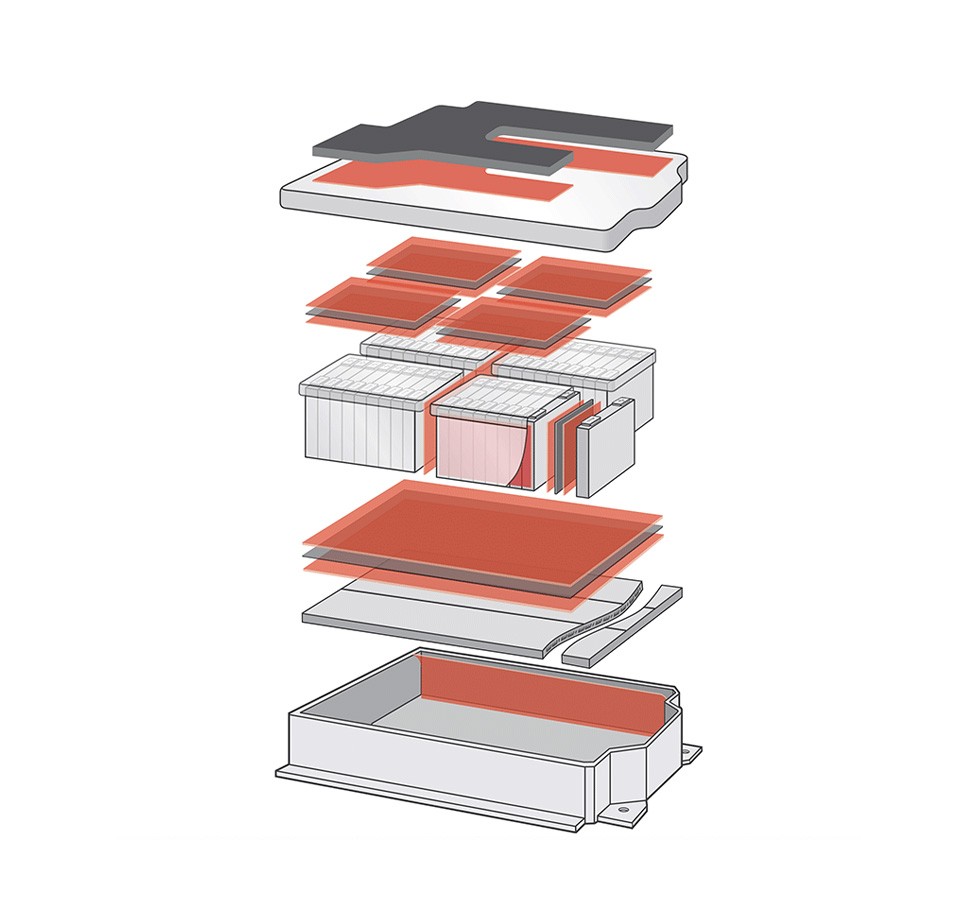

EV battery adhesives applications where our products are used

Our portfolio includes a wide range of functional bonding and protection tapes built on multiple pressure-sensitive adhesive technologies. These are engineered to make EV batteries safer, more efficient and easier to assemble.

Reduce flammability

Acrylic-, rubber- and silicone-based adhesives have Flame Tough™ flame-retardant properties that allow composites and materials to meet UL® 94 V-0 and other flame requirements.

Boost dielectric strength

Single-coated Volt Tough™ tapes and double-coated tapes which incorporate dielectric films. Our materials and adhesives are tested for breakdown voltage and dielectric strength requirements using GB/T 1408.1-2016 and ASTM D3755 test methods.

Optimize assembly

Functional EV battery tapes can replace mechanical fastening methods while offering a thinner profile, lighter weight, improved repositionability and an instant bond.

Stay in the know with Avery Dennison

Subscribe to an exclusive series of emails featuring information about the use of pressure-sensitive adhesive (PSA) tapes in Electric Vehicle Batteries (EVB).

Our team of EVB and automotive adhesive specialists, led by Automotive & eMobility Business Development Manager Max VanRaaphorst, will guide you through the solutions Avery Dennison offers for challenging applications in the EV Battery adhesives space. Discover how PSA tape solutions can help make EVB packs safer, more efficient and easier to assemble.

Subscribe for this exclusive content below, and you will receive the first email in your inbox immediately.

EV Battery Resources

Frequently askes questions about EV battery adhesives

-

What EV battery applications are Avery Dennison tapes designed for?

Our tapes are engineered to support the full spectrum of EV battery applications, from cell-to-cell bonding and thermal runaway mitigation to electrical insulation and pressure equalization. Whether you're designing battery modules or full packs, our solutions are purpose-built to meet the demands of thermal management, safety compliance, and lightweighting, all while streamlining production. We work side-by-side with OEMs and converters to deliver reliable, scalable adhesive tape technologies.

-

How do Avery Dennison adhesives enhance EV battery safety?

Battery safety isn’t optional, it’s essential. Our pressure-sensitive adhesives contribute to critical safety layers by providing high dielectric strength, flame-retardant properties and consistent thermal insulation. Our tapes can be used with materials like mica to play a key role in thermal runaway protection, helping contain heat and reduce the risk of propagation. With proven performance in demanding environments, our adhesives support safer batteries that meet regulatory expectations.

-

What standards are Avery Dennison tapes tested for dielectric strength?

Our EV battery adhesive solutions undergo stringent internal testing to meet high-performance thresholds for electrical insulation and dielectric protection. For instance, we test our products to ensure their dielectric breakdown meets ASTM D149 standards. While specific test standards may vary by application or OEM requirements, our materials are designed to support critical functions such as voltage containment and flame mitigation in high-voltage battery environments. As part of this process our internal burn chamber is used to test in accordance with UL® 94 standards. If third-party certifications or test protocols are required, our technical team can collaborate to support validation and documentation based on project needs.

-

How can Avery Dennison functional tapes help improve EV battery pack assembly?

Efficiency drives EV innovation, and our tapes are built to support fast, flexible, and precise assembly. Designed to replace and or support mechanical fasteners and liquid adhesive, our tapes offer cleaner installs, reduce part complexity, and enable automation. With solutions for gap filling, thermal interface management, and vibration damping, our functional tapes make battery pack construction simpler and smarter. They’re lightweight, clean to apply, and tailored to bond to today’s most challenging substrates. The result? More uptime, fewer errors, and faster paths to market.