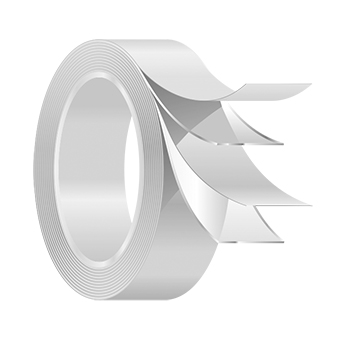

The Avery Dennison product portfolio includes a wide variety of constructions, chemistries, and functional additives. These products are backed by our superior customer service and technical support staff. You can be confident in your Avery Dennison solution.

We also have the ability to collaborate with you on custom solutions. Avery Dennison goes beyond bonding, offering you access to our research and development facilities and subject matter experts who can work with your team to produce the unique product you're seeking for your application.

Custom solutions

- Global footprint

- New product development for custom solutions for applications

- Business development and specification support for emerging applications

- Application engineering and technical support

Testing capabilities

- ISO 17025-certified laboratory

- Traditional pressure-sensitive adhesive bulk property testing (peel, tack and shear)

- Environmental conditioning (temperature, humidity, UV, chemical and more)

- Flame performance and dielectric strength testing at the tape and composite level