Adhesive tape solutions for battery venting

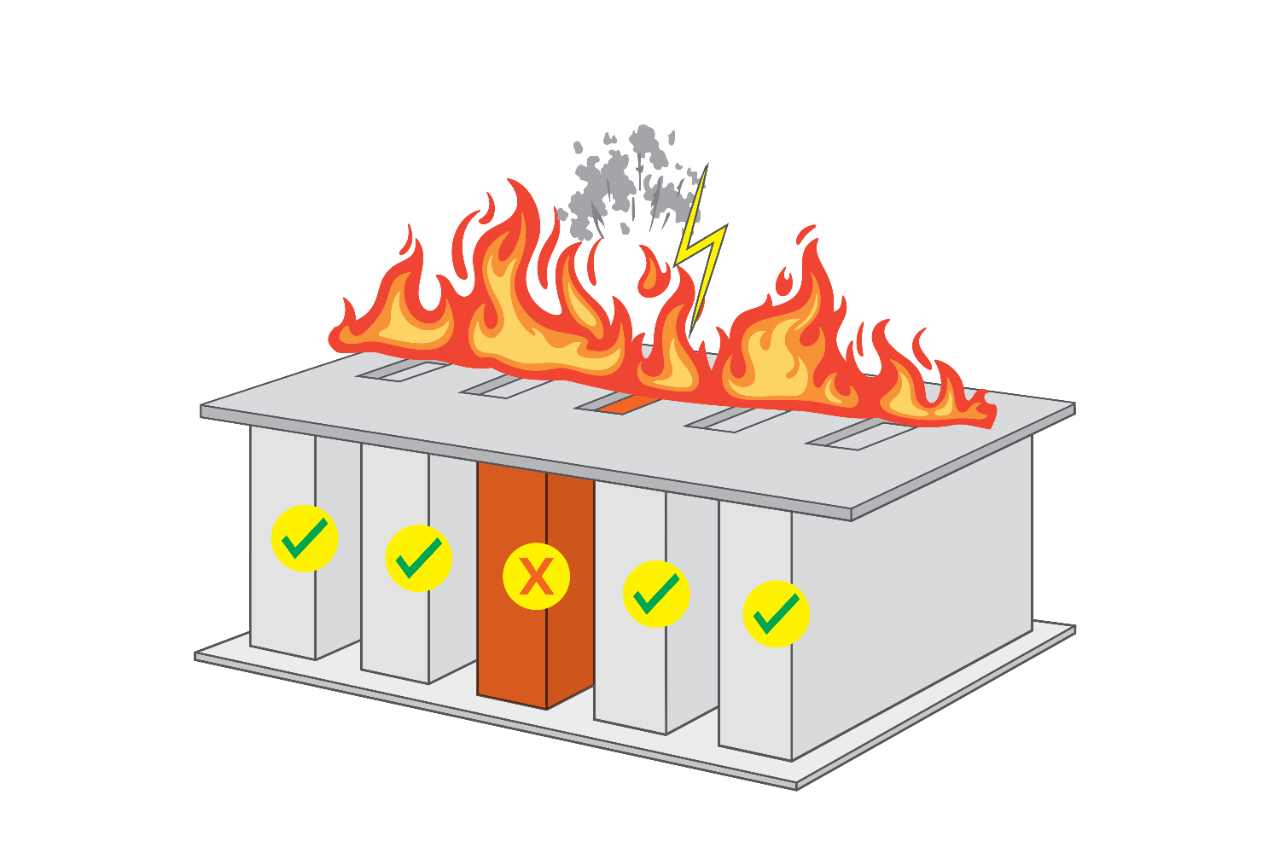

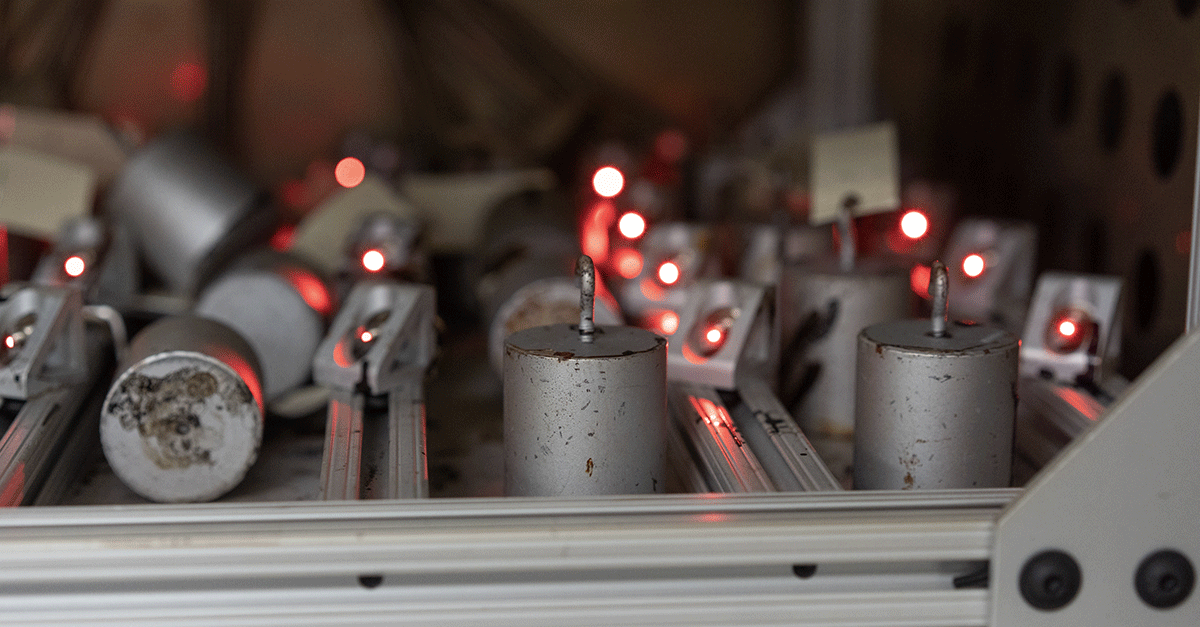

EV battery venting is a critical system-level function. When thermal runaway occurs, pressure must be released quickly, predictably, and without damaging the pack. Our pressure-sensitive adhesive (PSA) solutions are engineered for these events, providing high-performance bonds during normal operation, with controlled release when thermal thresholds are exceeded.

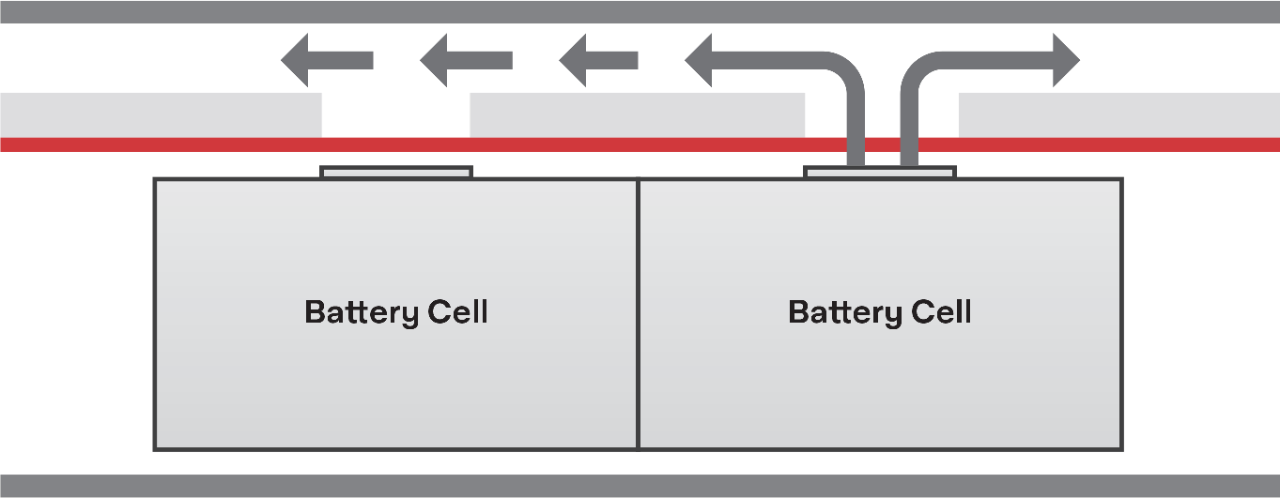

Anisotropic film tapes for directional venting performance

Venting adhesives must hold under stress, but release when the system requires it. Our anisotropic filmic tapes are tuned to respond to directional-dependent flame. This engineered failure mode ensures venting occurs precisely when needed, minimizing collateral damage to the battery structure and surrounding vehicle components.

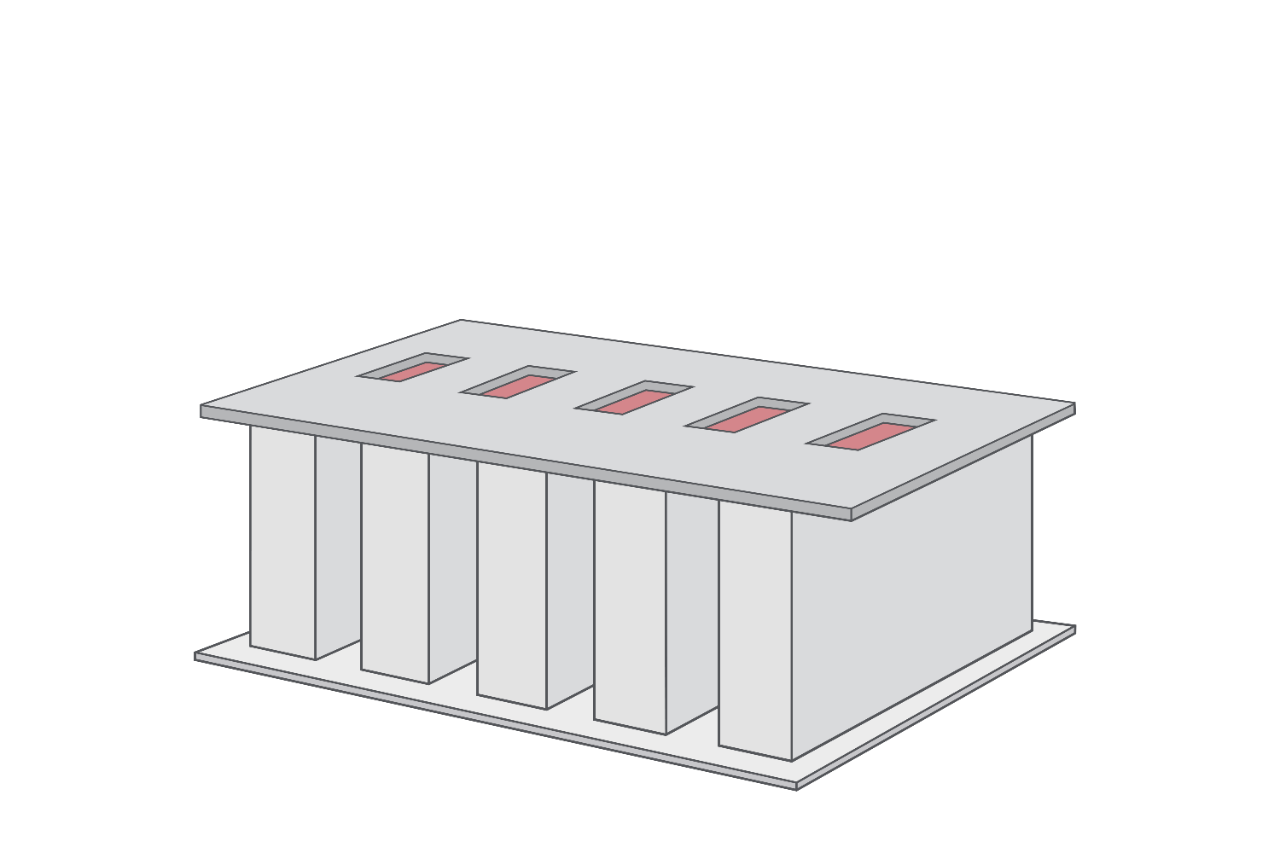

Tailored adhesives for vented and sealed packs

Battery venting system requirements vary by architecture:

Sealed battery packs require adhesives that function as permanent barriers, chemically resistant, heat stable, and vibration-tolerant across the service life.

Vented packs require adhesives that maintain bond strength under normal operation but release cleanly under elevated pressure or heat.

We offer adhesive constructions optimized for both use cases, with material options and release thresholds adapted to customer design intent.

Engineering challenges in venting adhesives

These applications demand performance across multiple axes. Our solutions are developed to address:

- Controlled release: Precise activation under targeted load conditions, no premature or delayed failure.

- Thermal and chemical exposure: Stability in contact with electrolyte vapors, pressure, and thermal cycling.

- Multi-material bonding: Proven adhesion across battery-relevant substrates: aluminum, polycarbonate, PET, foils, membranes.

- Aging resistance: Designed for consistent behavior at end-of-life, not just day one.

We collaborate with engineering teams to integrate materials seamlessly into evolving battery architectures.

Recommended venting adhesive technologies

We offer multiple material platforms to meet pack-level performance targets:

Anisotropic acrylic tapes: Engineered directional release, thermally stable.

Double-coated foam adhesives: Absorb vibration and allow for vent integration.

Transfer adhesives: Thin-profile, low-mass bonding with strong adhesion.

Laminated films: Reinforced structures for pressure management and system stability.

Performance and validation you can trust

Battery venting is a safety-critical system function. Our adhesives are validated under real-world simulations, including:

Thermal cycling and humidity aging

Peel, tack, and shear strength across materials

Compatibility with common electrolytes and chemical exposure

Consistent, predictable failure behavior

Testing is conducted in ISO 9000 and ISO 17025-certified labs. Many of our solutions meet UL® standards. We also support custom test protocols and integration guidance for customer-specific requirements.

Featured products

ES 3505

Specially designed, high-quality PET material with good fire resistance and insulation properties. Features a permanent, acrylic-based adhesive.

- Excellent die-cut, peel properties, and excellent sealing properties

- Specially designed high-quality PET material with good fire resistance and insulation properties

- Excellent tear resistance, high temperature resistance, and dimensional stability

- Suitable for various insulation applications

- Exceptional resistance to corrosion

ES 3507

High-quality ceramic fiber composite material with good fire resistance and insulation properties. Can withstand high-temperature impact of 800°C. Features a permanent, acrylic based adhesive.

- Excellent die-cut, peel properties, and excellent sealing properties

- Very high heat resistance and flame resistance

- Excellent tear resistance, high temperature resistance, and dimensional stability

- Suitable for various insulation applications

- Exceptional resistance to corrosion

FT 8065

Double-coated tape consisting of Flame Tough™ Acrylic and Flame Tough™ Polyester carrier. It is recommended for flame retardant and dielectric requirements within EV battery packs and similar applications.

- Enables composites to pass UL® 94 and other flammability requirements

- High tack

- Bonds well to low surface energy substrates and foams

- Dielectric, flame retardant carrier