Adhesive tape solutions for EV battery compression pads

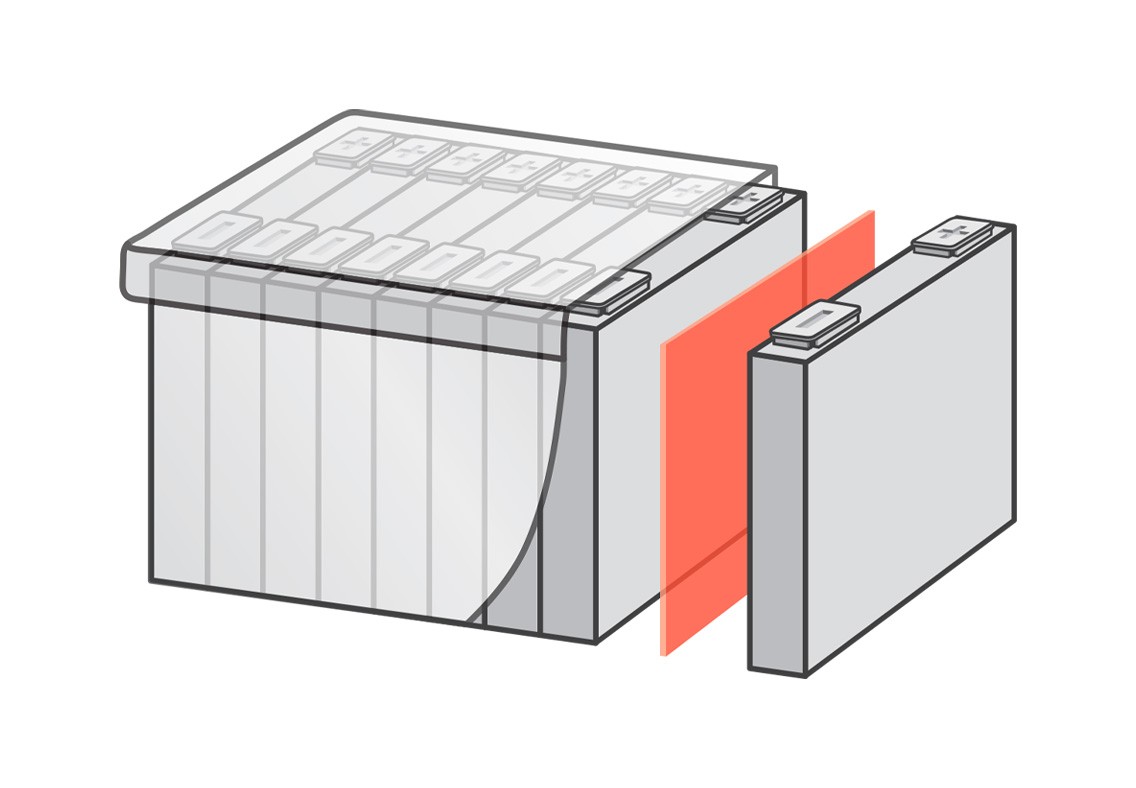

Avery Dennison offers multiple tape options for bonding compression pads in EV batteries. Individual prismatic and pouch cells in EV Battery packs need protection from impact and movement. Pouch cells can also swell during charging and discharging. To help prevent damage, EV battery manufacturers are placing foams backed with pressure-sensitive tape between each cell.

Pressure-sensitive tapes provide key benefits for cell cushioning.

Avery Dennison EV battery solutions offer multiple advantages for EV battery manufacturers.

Features

- No cure time with immediate strength

- Tapes can act as an assembly aid, unlike liquid-applied products

- Full coverage adhesion between the metalized polyester pouch cell and cushion foam

- Flame-retardant and dielectric tapes available

Featured products

FT 8065

FT 8065 is a double coated tape consisting of Flame Tough™ Acrylic and Flame Tough™ Polyester carrier. It is recommended for flame retardant and dielectric requirements within EV battery packs and similar applications.

- Enables composites to pass UL 94 and other flammability requirements

- Bonds well to low surface energy substrates and foams

- Adds dielectric strength and flame retardance where electrical insulation is needed to protect materials from high voltages and arcing

FT 8383 EZ

FT 8383 EZ is designed for bonding to a wide variety of polyester urethane, polyether urethane and polyethylene foams used in gasketing, sealing and sound dampening applications.

- Excellent processing and die-cutting stability

- Suited for a broad range of general purpose applications

FT 1123

FT 1123 is a 3.3 mil transfer tape with a modified acrylic adhesive. It bonds well to LSE materials and has good foam bonding properties.

- Highly conformable to curved or irregular surfaces

- Strong bond to low surface energy materials and good foam bonding performance

- Good heat resistance

- High tensile strength and tear resistance with excellent die cutting performance