Adhesive tape solutions for heater film bonding and gap filling

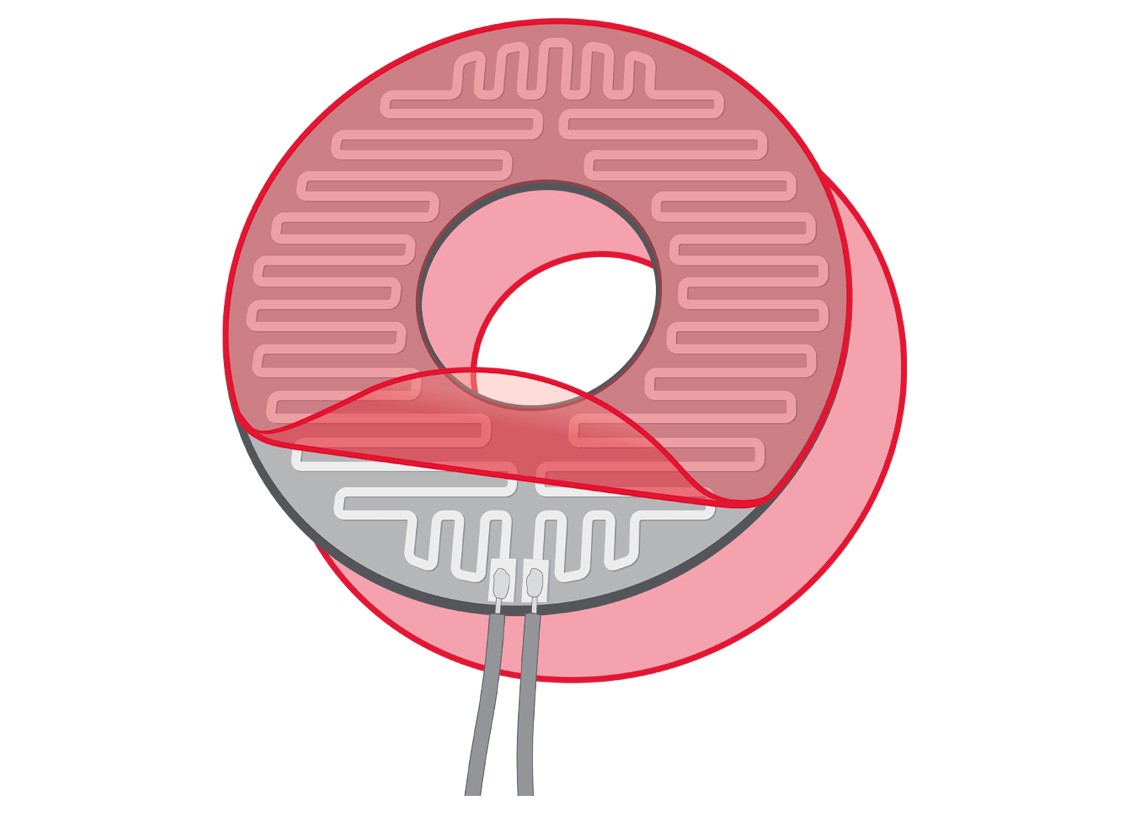

Avery Dennison offers tapes that meet the bonding needs of flexible heater films. With the use of tapes, it makes PTC heaters easier-to-assemble, lightweight and more durable. Printed, flexible heater films are an established solution for defrosting exterior mirrors. They’re being adopted for use with advanced driver-assistance system (ADAS) cameras and sensors, along with various applications in vehicle interiors to facilitate efficient heating. These systems need to perform flawlessly throughout a vehicle’s life and across a wide range of environmental conditions.

Pressure-sensitive adhesive tapes are an excellent choice for heater film bonding.

Avery Dennison offers a variety of tape solutions that can handle the challenging requirements of bonding flexible PTC heaters.

High-performance acrylic adhesives that withstand high temperatures and difficult automotive environments

Adhesives compatible with PTC heater conductive inks

Transfer tapes for thin profiles and double-coated foam tapes for filling gaps between rigid components

Featured products

HPA™ 1905

HPA™ 1905 is a 4.9 mil transfer tape with a high performance acrylic adhesive and a polyester release liner. It bonds well to medium and high surface energy plastics and metals.

- Highly conformable to curved or irregular surfaces

- High holding power to high and medium surface energy materials

- Excellent moisture stability and die cutting properties with good converting performance

- Two-year warranty

FT 1123

FT 1123 is a 3.3 mil transfer tape with a modified acrylic adhesive. It bonds well to LSE materials and has good foam bonding properties.

- Highly conformable to curved or irregular surfaces

- Strong bond to low surface energy materials and good foam bonding performance

- Good heat resistance

- High tensile strength and tear resistance with excellent die cutting performance

FT 1165

FT 1165 is a single-liner transfer tape of Flame Tough™ Acrylic, recommended for applications with flame retardant requirements.

- Enables composites to pass UL® 94 and other flammability requirements

- Bonds well to low surface energy substrates and foams

- Easier processing for lamination and die cutting