Feature: How pressure-sensitive adhesive solutions can help aerospace manufacturers and suppliers thrive

Drafted in collaboration with Avery Dennison Performance Tapes ADvantage Converter Network member, Sur-Seal

These are times of great opportunity and great challenge for the Aerospace industry. Demand is growing overall, and customers are particularly keen on aircraft that deliver greater performance and sustainability. However, global supply chain disruptions in recent years have many manufacturers and suppliers reconsidering the need to diversify their preferred material solutions. And companies across many industries, including Aerospace, are facing workforce shortages that are forcing them to find ways to optimize their processes.

These trends have trickled down and throughout the industry. Companies that respond will be poised to grow profitably through the 2020s and beyond. As the consulting firm Deloitte notes in its 2024 Aerospace and Defense Industry Outlook,

"Aerospace and defense companies should embrace new technologies and innovation to help navigate upcoming challenges and capitalize on growth opportunities. "

The analysts at Deloitte were referring primarily to new digital technologies — and the rapid adoption of such technologies surely should be a priority for the industry. But we believe other technologies can help Aerospace manufacturers overcome some key pain points in their manufacturing, and profitably produce aircraft that are aligned with the trends impacting the industry.

An introduction to PSA tapes

One such technology is pressure-sensitive adhesive (PSA) tapes. PSA tapes are used widely in industries such as Automotive, Appliances, Building and Construction, Electronics, General Industrial, Personal Care and Transportation. Generally, tapes are seen as an alternative to mechanical fasteners (such as screws, nuts and bolts, rivets) or liquid-applied adhesives. In fact, PSA tapes can do much more than simply bond materials — a key point that we’ll cover later in this article.

As a bonding solution, however, tapes excel. They’re growing in use in Aerospace, as they offer engineers a variety of advantages.

- A strong, consistent and resilient bond for permanent applications

PSA tapes meet many Aerospace manufacturer specifications for applications that require a permanent bond. They can also enable the joining of dissimilar materials with a continuous bond area. - Even distribution of stresses and strains

PSA tapes uniformly distribute stresses and strains, as they do not require holes to be punched or drilled in the substrates. This helps preserve the strength and integrity of the materials to be joined. - Chemical and weather resistance

PSA tapes are engineered to resist exposure to hydraulic fluid and other chemicals. Tapes are also subjected to environmental and temperature testing to ensure strength and durability across a range of conditions. - Temperature resistance

PSA tapes can offer long-duration resistance to the temperature extremes (-40 F to 500 F) encountered by an aircraft. - Flame retardancy

PSA tapes can be engineered to meet OEM specifications for flame retardancy, along with FAA requirements 25.853 and 25.855. - Lightweight

PSA tapes tend to be far lighter than mechanical fasteners. Lightweighting is a key tactic for manufacturers seeking to make aircraft more fuel-efficient. Greater fuel efficiency helps the industry be more sustainable.

Ease of use

PSA tapes are easy to work with and apply, either manually or through automated assembly. Unlike liquid-applied adhesives, they require no curing time. This ease of use can help manufacturers get more done with fewer resources.

Tape constructions

A typical tape construction consists of three parts: a filmic or paper carrier, an adhesive, and a protective liner. Depending on the needs of the application, a tape may be single-sided (a single layer of adhesive laminated to the carrier) or double-sided (a layer of adhesive on either side of the carrier). Double-sided tapes can also feature differential adhesives, which are useful when bonding dissimilar materials.

The adhesives at the foundation of these tapes are available in a wide range of chemistries. Avery Dennison, a leading global tape manufacturer based in Painesville, Ohio, offers hundreds of formulations in its product portfolio. Adhesives can thus be fine-tuned, to a very high degree, for the needs of an application. In fact, Avery Dennison frequently works closely with individual customers to custom-engineer adhesive formulations in its ISO-certified laboratory.

Converted tapes

It’s also quite common for tapes to be “converted.” They may be merged with functional materials such as flame-retardant fibers; rubber, plastic, graphite and foam seals; EMI/RFI shielding; silicone gap pads; and thermally conductive materials. Conversion also often involves precision forming or die-cutting, producing a tape-based solution based on a customer's exact needs.

Expertise in conversion is provided by companies such as Sur-Seal, an ISO 9000- and AS 9100-certified manufacturer based in Cincinnati. Sur-Seal has extensive experience in numerous industries, including Aerospace, Automotive, Energy, Heavy Equipment, Military, and Transportation. The company converts a wide range of MilSpec and ASTM-certified materials.

PSA tape manufacturers such as Avery Dennison and tape converters such as Sur-Seal often collaborate on projects that address customer opportunities. Besides the materials, these companies can provide a high level of scientific, engineering and process expertise. The sum is thus even greater than the parts: With both manufacturers contributing materials and expertise, the customer is ensured an optimal adhesive-based solution.

PSA tape applications for modern aircraft

Owing to their many advantages, PSA tapes are used in numerous applications in modern aircraft.

- Cabin liners

The inside of a modern passenger aircraft cabin is often lined with flexible plastic film, such as polyvinyl fluoride (PVF), polyamide, or PEEK. These films help provide flame retardancy and resistance to abrasions, chemicals and ultraviolet radiation.Securing these flexible films to rigid substrates with mechanical fasteners is not an option. PSA tapes, however, can do the job easily. A PSA can be formulated to bond to aluminum, painted surfaces, and substrates with differing surface energies, making it ideal for this application. - Carpeting

To adhere carpeting, one side of a double-sided PSA tape is bonded to an aircraft's interior honeycomb. The carpet is then laid down and bonded to the other side of the tape. Such tapes are lightweight and extremely durable. Formulated with flame-retardant additives, they’re engineered to self-extinguish according to FAA requirements 25.853 and 25.855. These tapes are also designed for easy removal. This can be a particular advantage if it’s decided to replace carpeting during an aircraft’s maintenance, repair and overhaul (MRO). - Insulation and structural damping

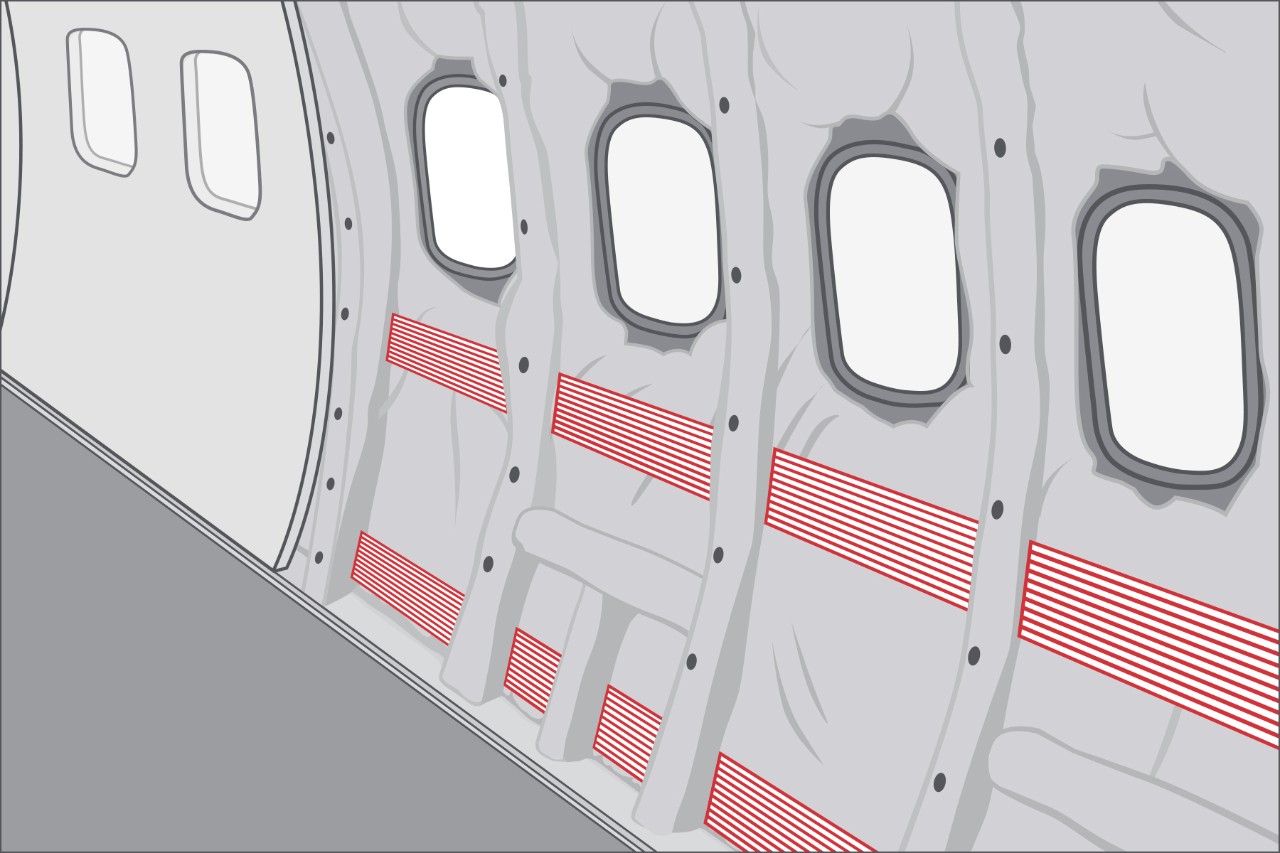

PSA tapes may be used to seam together thermal insulation materials before placing those materials between the plastic structure of the cabin and the aluminum frame of the fuselage. A single-coated tape may also be used in the cargo pit to seal compartment liners, bonding to the plastics and not the insulation material. Single-coated tapes may also be used to seal off aircraft acoustic insulation materials. These materials typically consist of glass, polyester, nylon, or other tough, fibrous materials. The carriers for these tapes can be made of similar materials. Finally, PSA tapes can be used to bond structural vibration-damping tiles directly to an aircraft’s fuselage interior. Adhesives used for this application can be formulated with specific rheological properties that aid in the damping function. - Masking

PSA tape solutions may be used to protect an aircraft’s windows while its outer skin is painted, coated, or sandblasted during manufacturing or MRO. These are single-coated foil tapes that require an adhesion that can resist high temperatures and chemicals but still be cleanly removed. They’re typically die-cut to the exact dimensions needed to protect the window while allowing precise application of paint or other treatments. This precise sizing of masking materials can save employees time and effort. Double-sided PSA tapes may be used to bond materials for sealing and gasketing to door and window frames. These include environmental and mechanical seals and gaskets, along with EMI/RFI shielding to help protect sensitive aircraft electronics and reduce or eliminate electronic interference. - Wire harnesses

Single-sided PSA tapes may be used to wrap aircraft wire harnesses. This helps shield them from abrasions and high temperatures while limiting any motion of the harness. Tapes encapsulating these fibers are often laminated with a scrim to provide puncture resistance against structures and piping. Metalized glass cloth may be used to act as a thermal barrier.

This list only scratches the surface of the potential applications for PSA tapes in modern aircraft. And as the aerospace industry grows with technologies such as electric and hybrid-electric propulsion, drones, and satellites and crewed spacecraft, the PSA tape industry is poised to grow with it.

Choosing a tape: The expertise factor

With so many adhesive chemistries, functional materials and constructions available, choosing the right tape for an aerospace application requires a thorough process. At a high level, an engineer must consider four factors:

- Properties of the construction’s carrier or functional material.

- Properties of the aircraft surface (or surfaces) being bonded to.

- Environmental conditions the tape construction will be exposed to throughout its service life.

- Tape format (single-coated, double-coated, etc.) required by the application.

The fact is, PSA tape selection often requires deep expertise with the application, adhesive chemistries and properties of various materials. Many applications additionally require capabilities such as material forming and die cutting. Aerospace manufacturers often do not possess such expertise and capabilities in-house.

However, companies such as Avery Dennison and Sur-Seal do possess them. And sharing this expertise and these capabilities is simply a routine aspect of their working with customers.

Getting started with PSA tapes

As the Aerospace industry is poised for a bright future, now is the time to evaluate new technologies such as PSA tapes. We welcome the opportunity to discuss your current materials and bonding solutions and investigate how PSA tapes might be a key part of how your business responds to industry trends. Avery Dennison and Sur-Seal want to be part of your profitable future.

Learn more at tapes.averydennison.com, and sur-seal.com.