Feature: What’s Cooking? PSAs in the Kitchen

The Avery Dennison Performance Tapes Interior Surfaces Portfolio offers bonding solution advantages for many kitchen building and renovation applications

With an increased amount of time in our homes brought about by Covid -19, many took on remodeling projects to pass the time. Having limited opportunities to be out and about, people turned their energy and dollars inward toward improving their homes. This trend has continued in the post-pandemic era and looks to persist in the coming years. According to Global Market Insights, the U.S. home remodeling market is expected to grow at a 4.5% CAGR from 2019 through 2026, ending that period at a value of $507.5 billion.

Homeowners are spending many of those dollars in the kitchen. According to the 2022 Houzz & Home Study published by Houzz.com, 27% of home interior remodeling projects in 2021 took place in the kitchen at an average cost of $15,000. The kitchen also was the most frequently remodeled interior space.

The kitchen remodeling industry needs new bonding solutions

But as home remodeling demand grows, the building and construction industry finds itself in a bind. The culprits? Inflation at 40-year highs, supply chain challenges and a construction labor shortage. Competition is as tight as ever for home renovation product manufacturers and architects, including those specializing in the kitchen space.

The industry is ripe for new kitchen remodeling solutions that are cost-effective, flexible, durable, and safe. They should not only be easy to manufacture but easy to use for professional contractors and DIY homeowners alike.

Enter tape products with high-performance, pressure-sensitive adhesives (PSA).

Pressure-sensitive adhesive tapes offer multiple advantages

PSA tapes are used in many industries, including automotive, aerospace, appliance, electronics, personal care and transportation. They’ve been adopted for many applications in building and construction as well. In many cases, they've been specified as a preferred alternative to mechanical fastening systems or wet-glue technologies.

Tapes can be purpose-built to fit an application's specific needs and address a range of technical challenges. The key to their growing adoption across these industries is often the versatility of the adhesives themselves. The Avery Dennison portfolio includes hundreds of adhesive formulations, each with specific properties, which can be paired with multiple carriers to solve a specific design challenge.

The bottom line? PSA tapes are easy to use, adhering quickly with no mess. They're versatile for a wide range of applications and can bond to challenging substrates. They’re strong and durable and can be formulated for low VOC, fire retardancy, and other safety features. They’re ideal for many remodeling applications, including those in kitchens.

Pressure-sensitive adhesive tapes in the kitchen

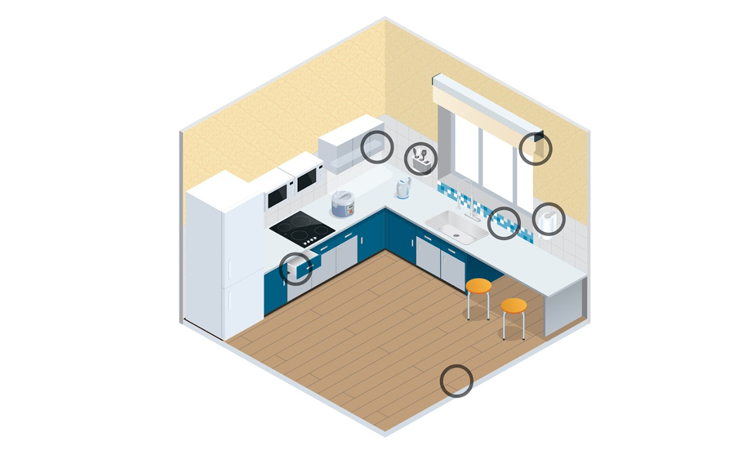

PSA tapes are particularly popular for those kitchen applications where traditional bonding systems are less than ideal. Examples include tight spaces or rented apartments where extensive and permanent kitchen renovations are not allowed. But with that said, tapes have the potential to work in a broad range of applications for commercial and residential kitchens.

So imagine, instead of the time-intensive process required to apply a wet adhesive to a floor before laying vinyl plank flooring, the contractor or homeowner simply peels a liner off the back of each plank and presses it into place. Or instead of mounting a task light with screws and a drill, the contractor puts it into place with a simple peel and stick. The ease of use and time savings can be game changers for kitchen remodeling.

Interior Surfaces Portfolio: A collection of tapes for kitchen applications

The Avery Dennison Interior Surfaces Portfolio of PSA tapes includes several that are suited for kitchen applications. We also commonly work with manufacturers across industries to develop custom adhesive formulations when no other solution can be found.

| Kitchen application | Common application needs | Avery Dennison pressure-sensitive adhesive suggested solution |

| Flooring (vinyl, laminate, tile) | Low VOC, durability, plasticizer resistance, ease of use | HPA 8320 - High performance, excellent plasticizer resistance to some of the vinyl flooring. Great low-VOC laminating system. Quick stick, robust, versatile double-coated high-performance tape |

FBA 7918 GL - General purpose, low VOC. Unique scrim supported for dimensional stability with conformable, quick bond attributes |

||

| Lighting | Quick and durable adhesion to multiple substrates, vertical and inverted shear-loaded mounting (e.g., under-cabinet lighting) |

FM 2316 - General-purpose acrylic foam tape ideal for dynamic shear demands |

FM 2454 - High performance, aggressive quick-stick double-coated foam tape for high shear demand. |

||

| Removable | Any short- to long-term mounting in kitchen spaces where gap filling is not critical |

FT 8310 - Double-coated permanent, removable adhesive. Laminates well to most substrates and removes cleanly; performs in room temperature and cold environments. |

Whether you’re a manufacturer or a tape converter serving the building and construction industry, know that PSAs are poised to help transform kitchen remodeling. We welcome the opportunity to discuss that transformation and see how we can help you use PSAs to take advantage of the remodeling boom.

Find out how our portfolio can help you deliver products in tune with the needs of today’s home improvement marketplace.