Feature: Logging on to the WeAutomotive EV Battery Online Learning Series

With the Covid-19 pandemic forcing the cancellation and postponement of so many trade shows and conferences, I jumped at the chance to attend WeAutomotive Group’s, “Content Lead EV Battery Tech—Innovation Webinars.” These were broadcast live for five days starting the week of June 22, so I could attend virtually from my home office.

Webinars were presented by a wide variety of companies working in the EV (electric vehicles) powertrain space. I picked the ones that were most relevant for my role at Avery Dennison® working with converters and suppliers to help grow their business. During the five days, I virtually attended presentations by FEV, H.B. Fuller, Neograf Solutions®, Lubrizol®, and Wildcat Discovery Technologies®.

Key takeaways

My primary takeaway revolved around the issue of battery cooling. There is clearly a lot of work being done to promote technologies that can effectively manage temperatures to ensure occupant safety by preventing vehicle fires and thermal runaway events.

• Immersive cooling technology from FEV and Lubrizol

Particularly eye opening was information presented by powertrain manufacturer FEV. It showed how 350 kW fast charging can cause enough heat to initiate a thermal runaway in traditionally constructed and cooled battery packs, with battery temperatures rising to over 60℃ in less than 16 minutes. As the EV segment grows and consumers demand their vehicles offer more of what we take for granted with internal combustion vehicles (longer range, faster “refueling” times, etc.), this is an engineering issue that needs to be addressed.

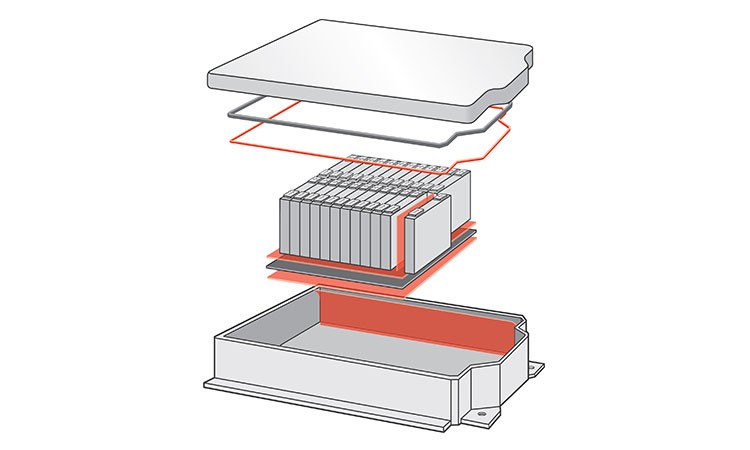

Working with specialty chemical manufacturer Lubrizol, FEV seems to have a solution in the works. It is called immersed battery cooling. With this, the battery pack is redesigned so the cells are immersed directly in a pool of flowing dielectric fluid. Because the fluid is nonconductive, the coolant and cells can be in direct contact. This is unlike water/glycol chiller plates which have less contact with the lithium-ion battery (LIB) cells. This allows the fluid to more efficiently remove heat from the battery. The pack can actually be preconditioned to maintain an optimal temperature of between 0 – 40℃.

• Graphite-based cooling system from NeoGraf Solutions

NeoGraf Solutions provides graphite and carbon products to a variety of industries, including automotive. Also with an aim of more effective battery cooling, they showed off a system using their thin sheets of graphite—which has high thermal conductivity—to quickly remove heat from battery cells. The graphite sheets can then transfer that heat to a standard chiller plate.

• Fire-retardant foam from H.B. Fuller

Specialty chemical manufacturer H.B. Fuller presented their 5x expansion foam encapsulation product, which can assist in starving oxygen from a fire. The product appears to work well to encapsulate cylindrical battery cells from fire, and to simply retain the cells within each module. This polyurethane foam appears to be less of a thermal runaway inhibitor and more for fire suppression though, and is probably less ideal for pouch cells or prismatic cells than for cylindrical cells. Still, it is a promising, new option for the right kind of application.

• Making progress

As we continue to progress toward a future of more EVs, issues such as battery cooling have to be addressed and solved. While much work remains, companies such as FEV, Lubrizol, NeoGraf Solutions and H.B. Fuller are definitely making progress. These are challenging engineering issues being addressed with real creativity and innovation.

I am confident that there is also a wealth of opportunities for adhesive tape converters in the EV space. Avery Dennison can help. Our battery solutions—many of which can be customized to meet UL® 94 V-O and other requirements—address issues such as LIB bonding, venting, ASSB technology, and thermal impedance adhesives for passive cooling. I welcome the opportunity to discuss how we can put our performance engineered solutions to work for your business.

Michael VanHaerents is an automotive segment business development manager for Avery Dennison Performance Tapes. He leverages 18 years of adhesive and sealant engineering and program management experience in the automotive industry to help build strategic relationships, create product specifications, and build new technology portfolios for new and existing adhesive and tape applications. Based in the Detroit area, he can be reached at michael.vanhaerents@averydennison.com, and welcomes your connection on LinkedIn. LinkedIn.