Adhesive tape solutions for gasket bonding

Avery Dennison offers adhesive bonding solutions for foam gaskets commonly used in automotive electronics applications.

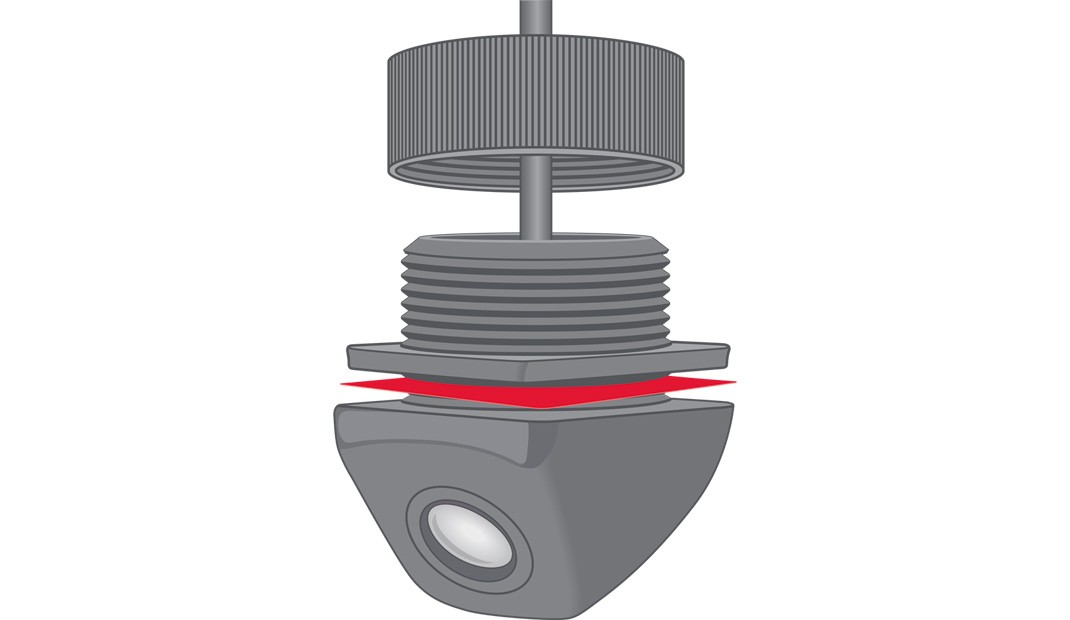

Gaskets are critical to prevent moisture contamination. When a camera or sensor is mechanically fastened to the vehicle, one or more gaskets may be used to provide a permanent seal. This seal prohibits ingress of moisture and other contaminants while allowing the camera or sensor to be removed and serviced.

Pressure-sensitive adhesive tapes are a durable bonding solution for gaskets.

Seal around the component for added durability, ingress protection and buzz/squeak/rattle reduction

Provide gasket materials with a thin and instant bonding solution

Double-coated tapes add dimensional stability to gaskets, preventing stretch upon application

Featured products

FT 1126

FT 1126 is a 5.2 mil transfer tape with a modified acrylic adhesive. It bonds well to low surface energy materials and has good foam bonding properties.

- Highly conformable to curved or irregular surfaces

- Strong bond to low surface energy materials and good foam bonding performance

- Good heat resistance

- High tensile strength and tear resistance with excellent die cutting performance

FT 8327

FT 8327 is a 4.6 mil double coated polyester with a foam bonding rubber adhesive on the laminating side and a high shear rubber adhesive on the mounting side. It bonds a wide variety of foams to low surface energy materials.

- Dimensional stability and good die cutting characteristics

- Excellent foam bonding performance on a wide variety of foams

- Strong bond to a wide variety of low surface energy materials and high shear

- High tensile strength and good converting performance