Adhesive tape solutions for thermal interface materials in EV batteries

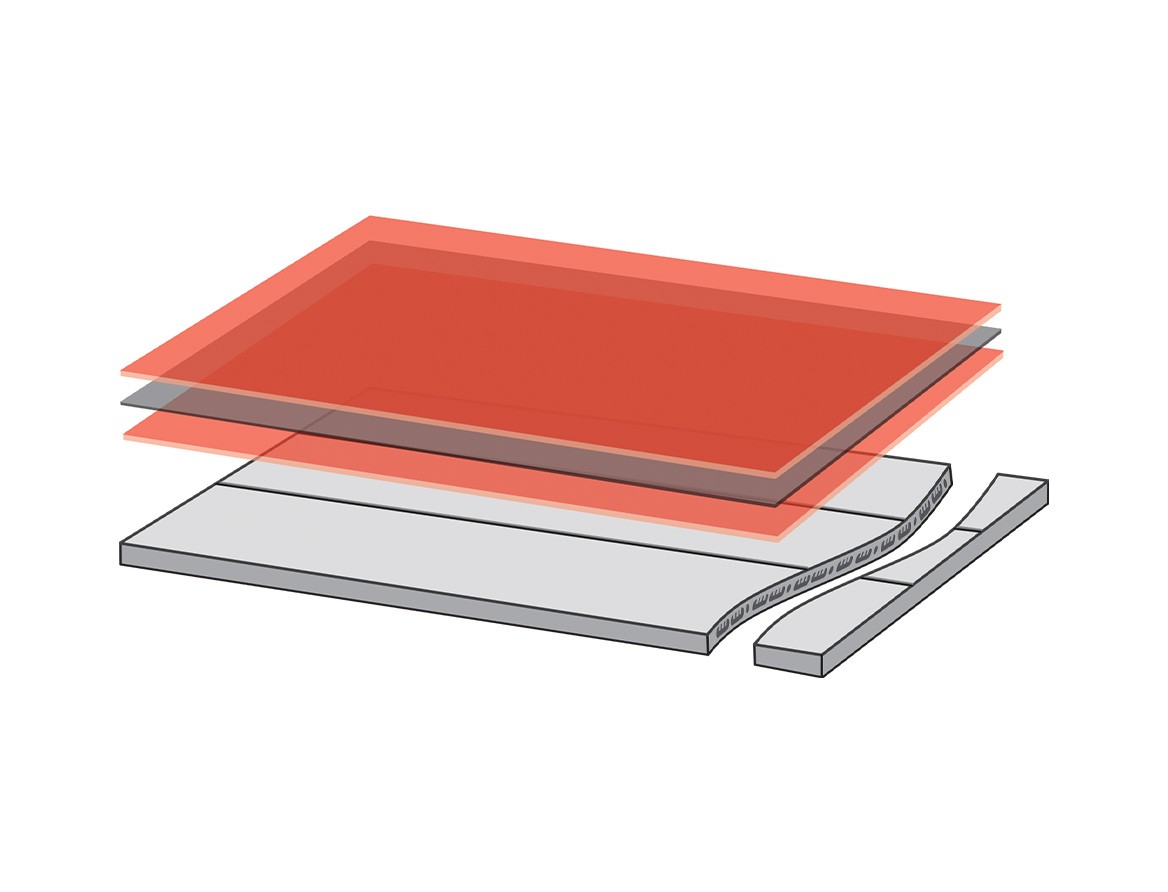

Avery Dennison offers multiple bonding solutions for thermal interface materials (TIMs). TIMs are a crucial component in EV batteries as they facilitate the transfer of heat between components in the assembly.

Pressure-sensitive adhesives for TIMs

Avery Dennison offers multiple adhesive bonding solutions for TIMs bonded to either heat sink or chiller plate materials to assist with battery cell and battery module cooling.

- Two, high wet-out adhesives to lower thermal impedance between TIM and heat source

- A silicone-based pressure-sensitive adhesive offering excellent adhesion to silicone TIMs in EV batteries

- An acrylic-based pressure-sensitive adhesive offering excellent adhesion to non-silicone based TIMs

- Flame-retardant adhesives tested in accordance with UL® 94 V-0

Featured products

FT 3075

FT 3075 is a double-linered transfer tape of Flame Tough™ Silicone recommended for difficult flame retardant requirements within EV battery packs and similar applications.

- Enables composites to pass UL 94 and other flammability requirements

- Bonds well to silicone foams and PTFE materials

- Adds high temperature creep resistance for demanding applications

FT 1123

FT 1123 is a 3.3 mil transfer tape with a modified acrylic adhesive. It bonds well to LSE materials and has good foam bonding properties.

- Highly conformable to curved or irregular surfaces

- Strong bond to low surface energy materials and good foam bonding performance

- Good heat resistance

- High tensile strength and tear resistance with excellent die cutting performance

FT 1165

FT 1165 is a single-liner transfer tape of Flame Tough™ Acrylic, recommended for applications with flame retardant requirements.

- Enables composites to pass UL® 94 and other flammability requirements

- Bonds well to low surface energy substrates and foams

- Easier processing for lamination and die cutting