Type of Substrates

In most applications, two substrates are involved. One will bond with the unwind adhesive during the converting process and is called the “lamination” substrate. The other will bond with the liner side adhesive and is called the “mounting” substrate. Substrates come in many different forms and substances – however, a few characteristics are key:

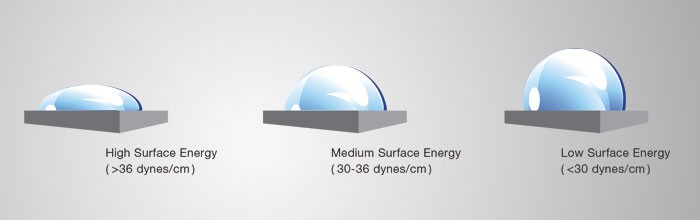

Surface Energy

The surface energy of a substrate will affect the adhesive’s ability to ‘wet out’ or spread over the substrate. Low Surface Energy (LSE) materials resist adhesive wet out, making bonding more difficult. However, high surface energy materials allow excellent wet out and provide the best adhesion.

For example, picture an unwaxed car when it rains. The water spreads out (or wets out) on the car creating puddles. In this case, the car’s surface is displaying high surface energy. However, a waxed car will cause water to bead up because the car’s surface is displaying LSE characteristics. Since pressuresensitive adhesives bond well when they can wet out, they bond well to high surface energy materials (the unwaxed car) but not so well to LSE materials (the waxed car).

Rubber based and modified acrylic adhesives typically offer better adhesion to LSE substrates, as they are softer and flow better. Some materials will require corona treating, primers or top coating to promote better adhesion.