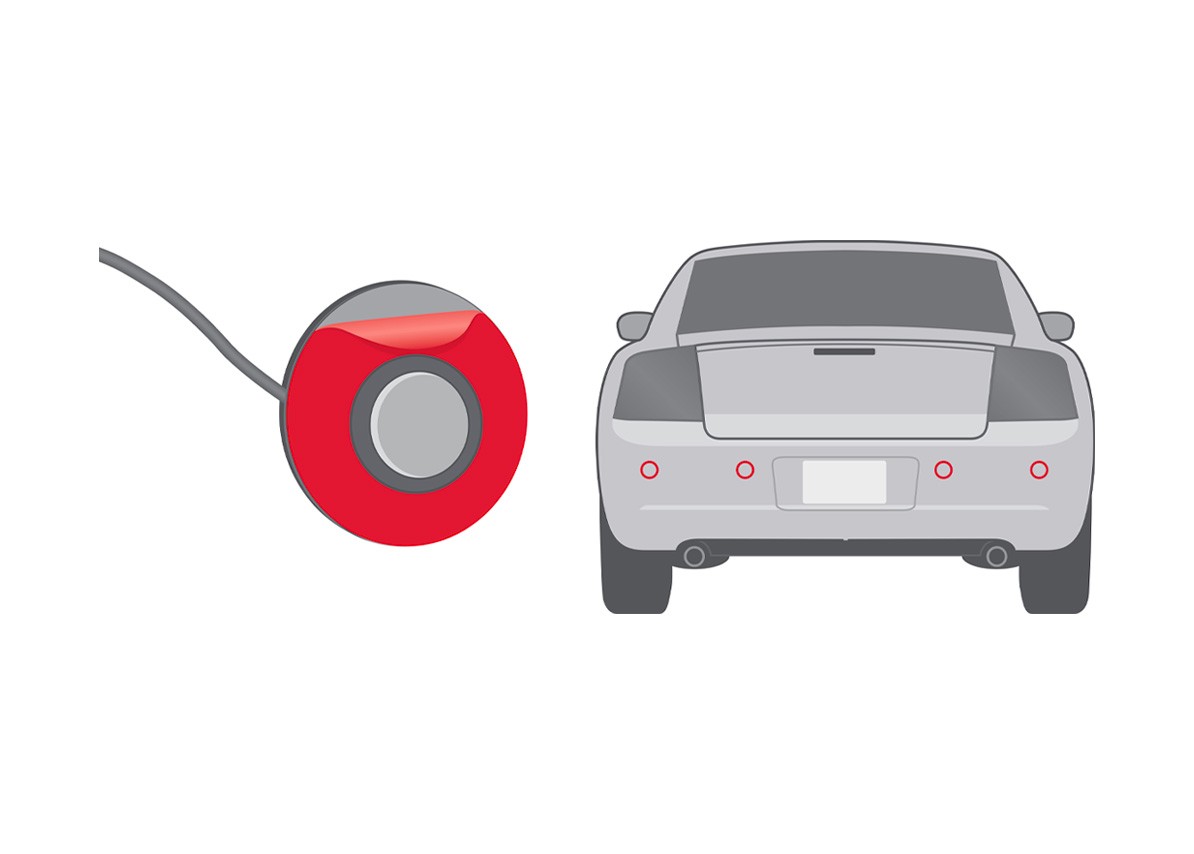

Adhesive tape solutions for sensor mounting and sealing

Avery Dennison offers tapes used to mount and seal sensors used in automotive ADAS features. The tape products help protect the sensors from moisture and other contaminants.

Consumer demands for increased safety have led to the development of advanced driver-assistance systems (ADAS) featuring automotive sensors. These systems’ cameras, ultrasonic sensors, radar, lidar and other sensors must be mounted on or near the vehicle’s exterior. Their often-delicate systems must also be protected from moisture and other ingress factors.

Pressure-sensitive adhesives are a offer multiple benefits for sensor mounting and sealing.

Avery Dennison double-coated foam tapes are a suitable solution for mounting and sealing products commonly available in the automotive sensors market.

Allow for a thinner, lighter mounting design than mechanical fittings and fasteners

Seal around the hardware for added durability and ingress protection

Absorb vibrations to help ensure sensors and cameras function optimally

Featured products

FM 2465 WPET

FM 2465 WPET is a 36 mil double-coated black polyethylene foam tape with acrylic adhesive on both sides. It was specifically designed for bonding automotive mirrors to mirror housings.

- High holding power

- Great heat, humidity and solvent resistance

- Good for filling and bonding rigid materials

FM 2116

FM 2116 is a 68 mil double coated white polyethylene foam with a high shear rubber adhesive. It bonds to a wide variety of low surface energy materials and features high shear strength and the ability to fill gaps.

- High holding power

- Great heat, humidity and solvent resistance

- Good for filling and bonding rigid materials

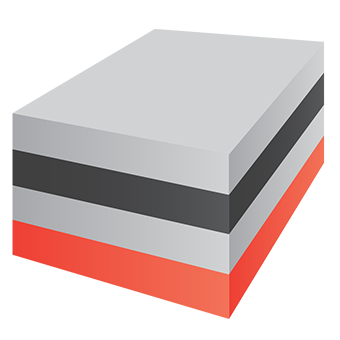

AFB™ 6111B

AFB™ 6111B is a black acrylic double-coated foam tape with multipurpose acrylic adhesive on both sides.

- High adhesion combined with good shear absorbs shock and distributes stress evenly

- Good moisture, UV and high temperature resistance

- Uniform bonding performance

- Helps eliminate the need for mechanical fasteners, drilling or grinding and related clean-up for certain applications