-

Performance Tapes

- Global

- Europe

-

Avery Dennison Corporation

- North America

- Asia Pacific

- Europe

- South America

-

Environmental, Social, Governance (ESG)

- Global

-

Automotive Solutions

- Global

-

Avery Dennison Medical

- Global

-

Fastener Solutions

- Global

- Asia Pacific

-

Graphics Solutions

- North America

- Europe

- Latin America

- Asia Pacific

-

Hanita Coatings

- Global

-

Inks

- North America

-

Label & Packaging Materials

- Europe

- North America

- Latin America

- Asia Pacific

-

Muse

- Global

-

Personal Care

- Asia Pacific

- Global

-

Performance Polymers

- Global

- Europe

-

Apparel Solutions

- North America

- Asia Pacific

- newness

-

RFID

- Global

- Europe

- Asia Pacific

-

Reflective Solutions

- Global

-

Yongle

- Global

- Asia Pacific

-

Identification Solutions

- North America

- Europe

-

Mactac

- EMENA

- Asia Pacific

-

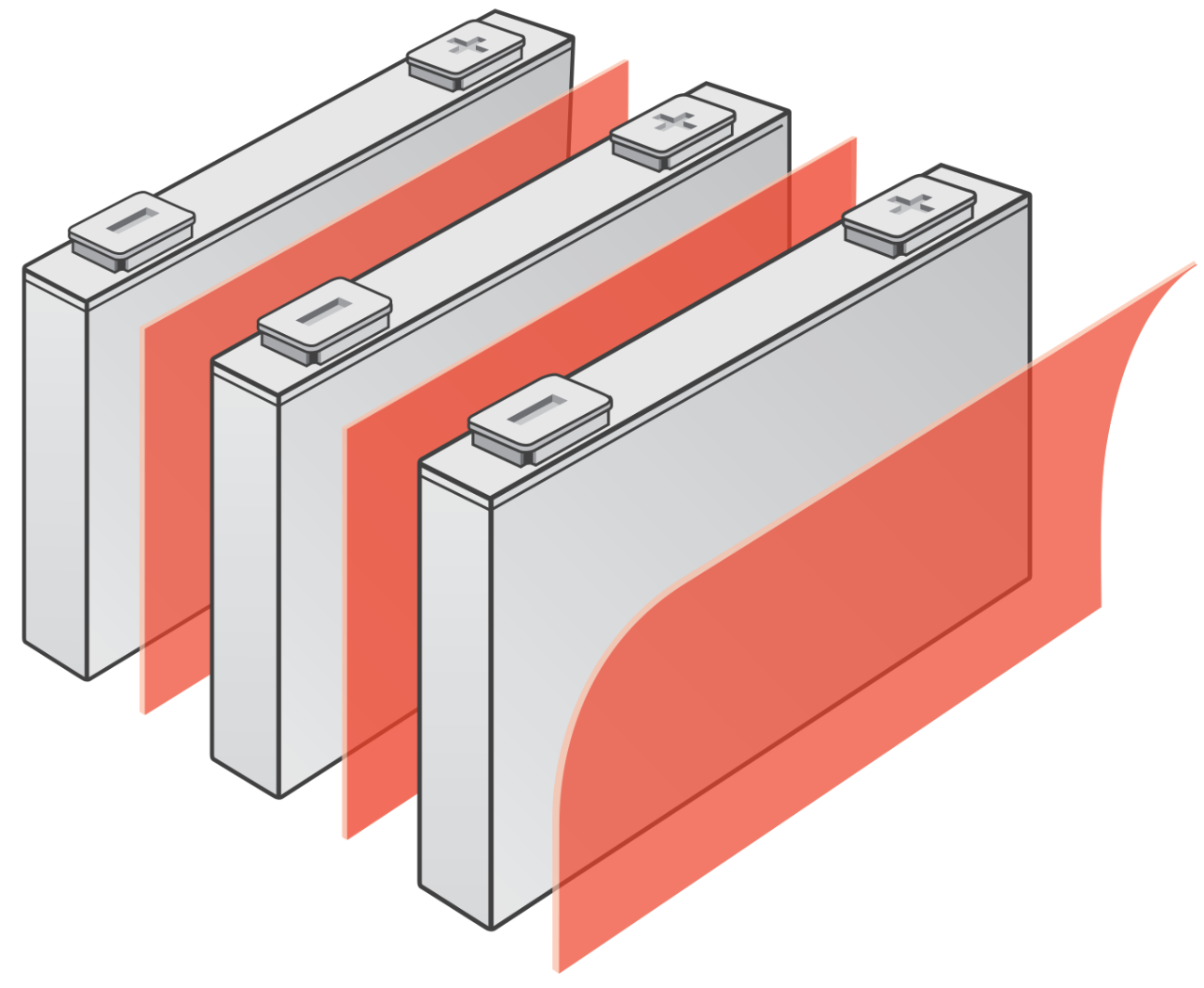

Electrified

- North America